Supply Chain Visibility Is Evolving Into a Real-Time Execution Engine

For years, supply chain visibility was treated as a dashboard, a passive layer that showed what was happening, where it was happening, and who might eventually panic about it. But that era is over. Modern logistics doesn’t reward spectators; it rewards orchestrators. And today’s organizations need visibility that doesn’t just inform operations, it needs to drive them.

Across industries, the shift is unmistakable. Global supply chains are operating at 10–15× the complexity they did a decade ago. Customer expectations have compressed delivery windows to hours, not days. Disruptions now occur every 3.7 minutes on average across large global networks. The old “track and trace” mindset cannot keep up.

This is where next-generation supply chain visibility solutions are stepping in not as dashboards. But as engines capable of making decisions, triggering workflows, predicting risks, and keeping execution aligned with business goals in real time.

Why Traditional Visibility Is No Longer Enough

Conventional visibility tools were built for transparency, not intelligence. They told teams what had already happened, a delayed shipment, a route deviation, a low inventory threshold, but left the rest to manual firefighting.

These systems suffer from three major limitations:

1. Visibility Without Action:

Tracking alone does not solve delays. Teams still rely on calls, emails, and spreadsheets to intervene. The result? Slow response times and inconsistent exceptions handling.

2. Fragmented Data Sources:

Supply chains now span multiple carriers, regions, partners, and modes. When data doesn’t sync, execution suffers. According to recent industry reports, 65% of disruptions escalate because teams lack real-time consolidated data.

3. Zero Predictive Capability:

By the time legacy systems alert you, the damage is already done. As a result, organizations are moving toward supply chain visibility software that integrates data, detects anomalies instantly, and triggers automated actions without waiting for human intervention.

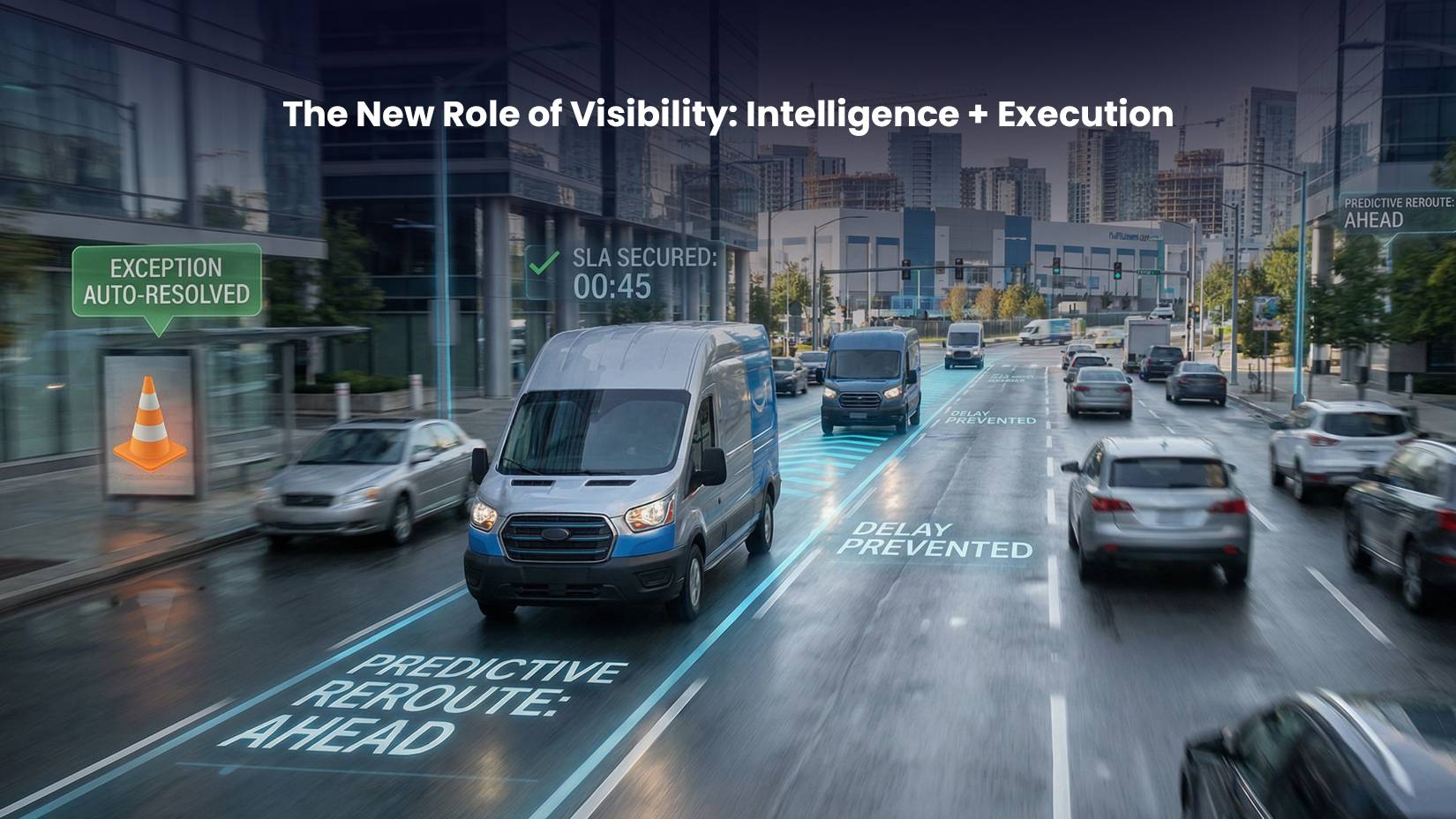

The New Role of Visibility: Intelligence + Execution

Modern visibility platforms aren’t content with being rear-view mirrors. They now serve as an active execution layer anticipating disruptions, adjusting workflows, and enforcing SLA-driven responses.

This evolution is driven by three core shifts:

1. Real-Time Data Flows Enable Proactive Decisions:

The rise of IoT, unified APIs, and cloud-native architectures gives organizations access to live data streams across their entire network. What used to take hours now happens in seconds.

2. AI and ML Turn Signals into Actions:

Predictive models can now foresee ETA slippages, weather risks, capacity shortages, and route inefficiencies before they hit operations.

Modern systems don’t merely alert teams, they automatically:

– Reassign carriers

– Trigger a route calculation

– Notify customers

– Open an exception ticket

– Apply business rules for escalation

This automation is the backbone of end-to-end supply chain visibility.

3. Workflows Become Rule-Driven, not Effort-Drive:

Organizations no longer want people running behind problems; they want problems sorted before people notice. Smart rules, SLA-based, geography-based, and event-based, activate corrective actions the moment a risk is detected.

With this, visibility transforms from descriptive to prescriptive.

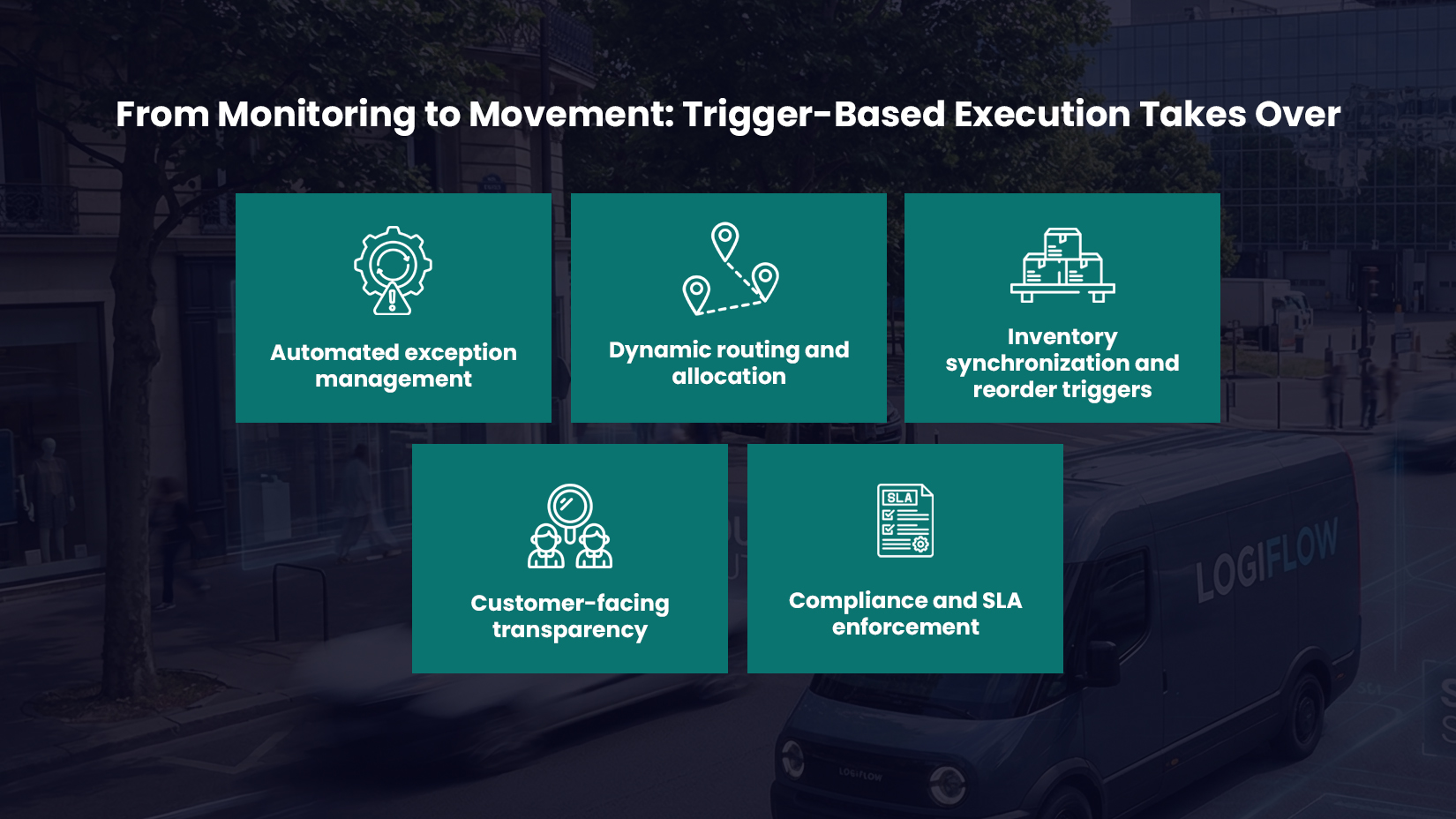

From Monitoring to Movement: Trigger-Based Execution Takes Over

If tracking was Phase 1 and prediction was Phase 2, automation sits at Phase 3, the phase where visibility becomes an execution engine.

Here’s how leading supply chain visibility platforms are redefining operations:

1. Automated Exception Management:

Over 70% of operational delays stem from unmanaged exceptions. Modern systems classify issues automatically, wrong scans, temperature breaches, detention risks and trigger resolutions instantly.

2. Dynamic Routing and Allocation:

AI-powered routing adjusts delivery paths on the fly based on weather, congestion, or vehicle status. Some industries report up to 22% faster deliveries after automating route adjustments.

3. Inventory Synchronisation and Reorder Triggers:

Retailers using modern visibility tools report up to 30% fewer stockouts, thanks to automated replenishment triggers tied to demand and movement patterns.

4. Customer-Facing Transparency:

With customers expecting live tracking (85% do), visibility tools trigger real-time updates that reduce WISMO calls by up to 45%.

5. Compliance and SLA Enforcement:

When shipments drift off SLA thresholds, systems instantly alert carriers, generate corrective workflows, and flag risks before escalation.

This is execution, not oversight.

What End-to-End Visibility Looks Like Today

True end-to-end supply chain visibility now covers not just freight in motion, but upstream planning and downstream fulfillment. This holistic approach is powered by data flowing freely across:

– Manufacturers

– Warehouses

– Carriers

– Distributors

– Retailers

– Last-mile partners

Companies with fully integrated visibility report:

– Up to 50% reduction in disruption impact

– 25–40% improvement in OTIF

– 15–20% lower logistics costs

– 2× better customer satisfaction

The gap between companies with modern visibility and those with outdated systems is widening rapidly.

The Future: Visibility Becomes the Command Center

The industry is moving toward intelligent control towers where visibility, prediction, and execution converge. By 2028, over 70% of global enterprises are expected to run automated, AI-driven supply chain command centers.

This future is built on systems that:

– Trigger actions instantly

– Learn continuously

– Adjust autonomously

– Scale globally

And at the heart of all this lies the evolution of visibility, from something that once reported events to something that now runs them.

Also Read: Inside 2025: Five Supply Chain Moves That Changed Everything

Final Word

The logistics world doesn’t need more dashboards. It needs engines. Systems that push operations toward resilience, accuracy, and consistency even when volatility spikes.

As disruptions become the norm rather than the exception, companies investing in modern supply chain visibility platform capabilities are the ones staying ahead. What began as a tracking layer has now become the operational heartbeat of global supply chains.

The message is clear: Visibility isn’t a window anymore, it’s the ignition switch. So, in order to stay ahead you need the best software available in the market buy LogiNext. So, click on the red button and book a demo today.

4

@LogiNext