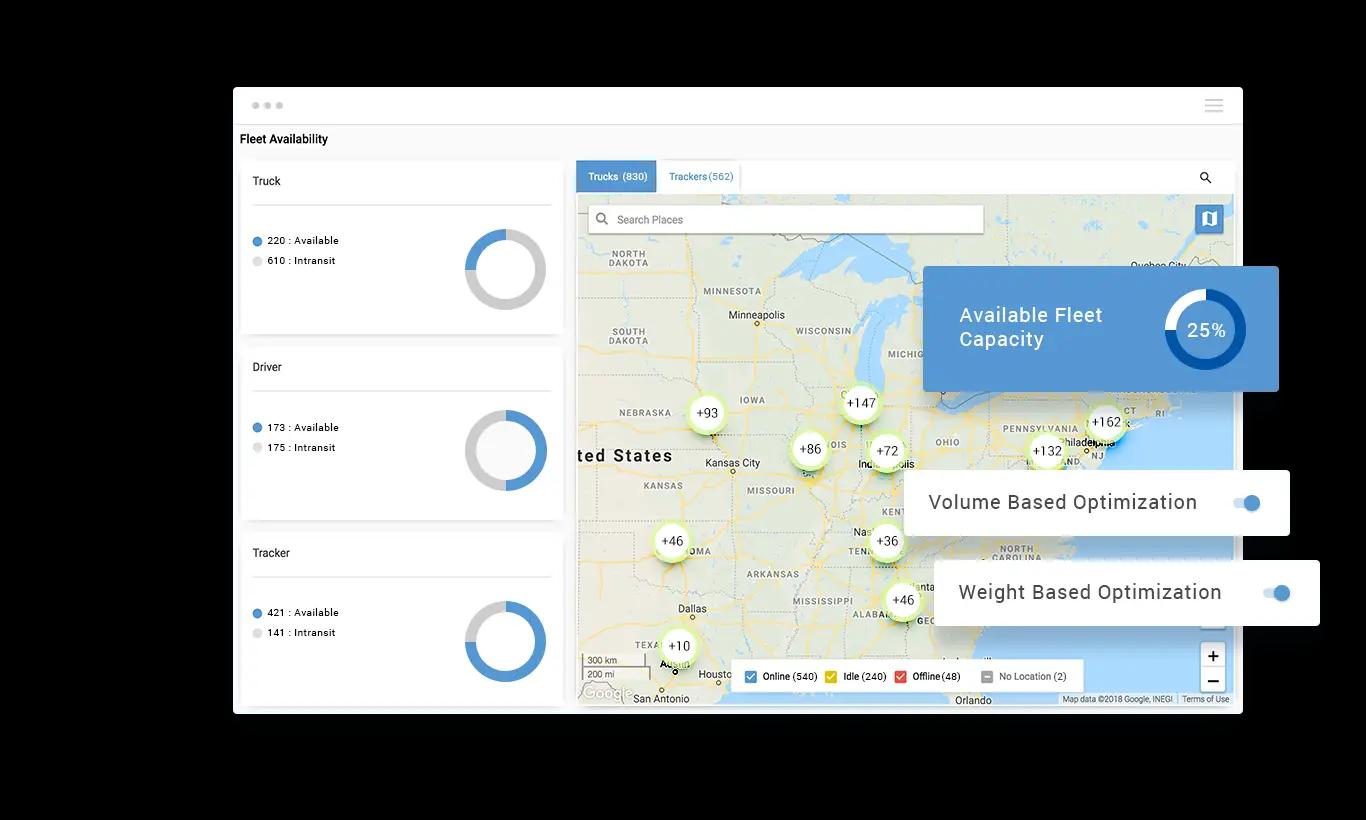

Plan your fleet capacity to perfection

Know exactly how many owned or third-party fleet capacity would be needed to fulfill incoming orders. Utilize all available fleet capacity to the fullest to bring down overheads with expert consolidation.

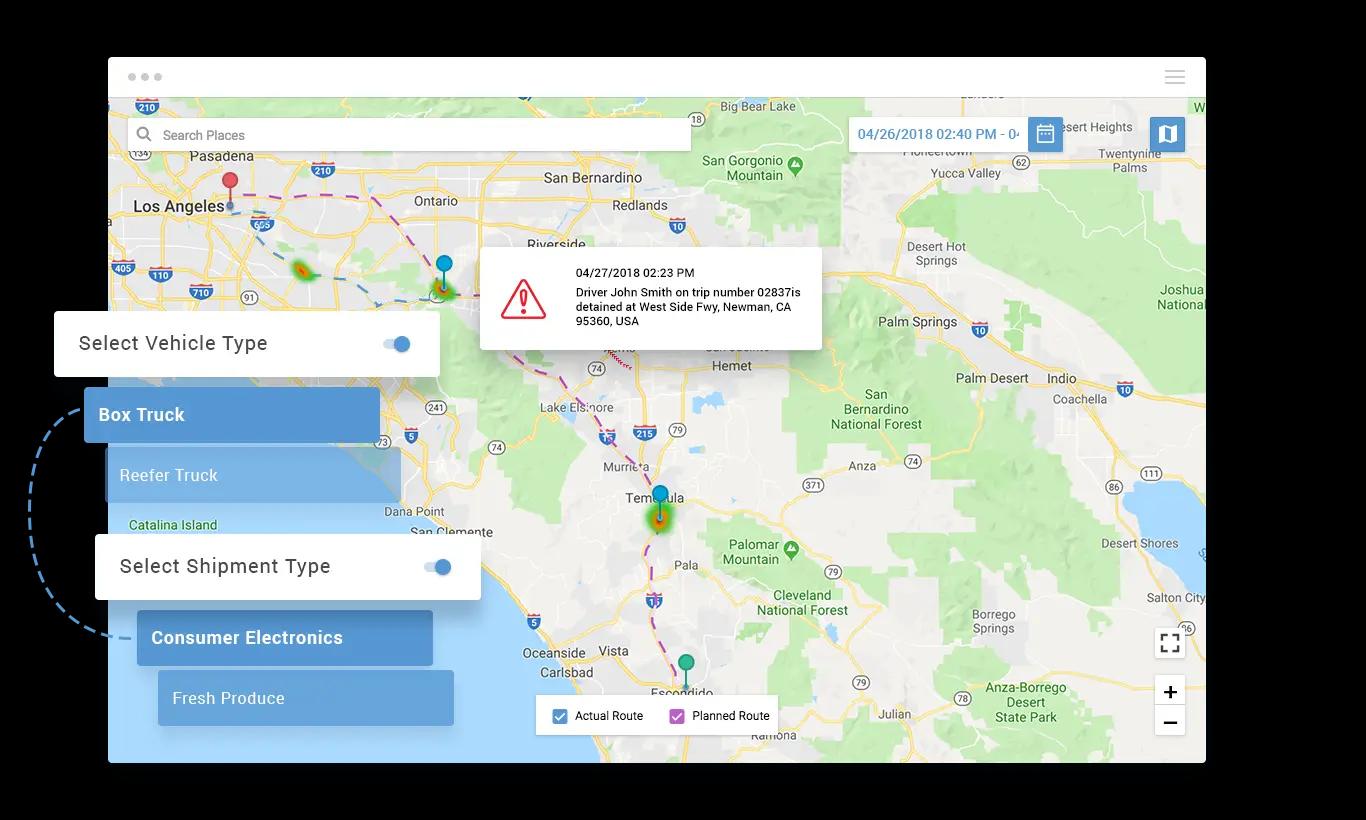

Easily sort all types of loads

Sort general, fragile, hazmat, etc. load as per their requirements, in quick time.

Match load to type of truck

Sort and load shipments to the right type of truck, whether reefer, box truck, etc.

Easily sync OMS and WMS

Seamlessly integrate with OMS, WMS, or any legacy system for fast shipment processing.

Hub-in hub-out reports

Know, in real-time, exactly when a truck enters or leaves any hub, with instant alerts.

Reduce hub-level detention

Fast scanning and unloading with clear incoming shipment alerts, reduce hub detention.

Reduce turnaround time

High capacity utilization with an optimized delivery schedule reduces turnaround time.