How the Pandemic Changed Manufacturing and the Role of Logistics Management Software

The pandemic led to a surge in demand for electronics and home appliances. As people spent more time indoors, they bought more of these items. However, production faced setbacks due to lockdowns and social distancing. This created a backlog of unmet demand. Logistics management software (LMS) played a crucial role in managing this surge and backlog. By optimizing supply chains, tracking inventory, and managing transportation, this software helped manufacturers streamline their operations and address the delays caused by the pandemic.

When economies reopened, orders for manufacturers surged. However, many needed help to keep up due to parts and labor shortages. Even now, some struggle with high prices and delivery delays. The demand for new durable goods like appliances, cars, and electronics peaked in March 2023. Since then, orders have slowed but labor shortages persist. Attracting skilled workers is a constant challenge, especially for specialized roles.

Deloitte forecasts up to 3.8 million more manufacturing jobs between 2024 and 2033. They also predict that 1.9 million of these jobs will need higher-level skills.

The pandemic was a big test for global supply chains. The Just-in-Time (JIT) inventory system failed due to disruptions. Many shifted to Just-in-Case (JIC) inventories, keeping extra stock to stay afloat. This approach protects against price hikes and supply issues. But it also meant higher costs for storage and interest. As things eased, manufacturing returned to JIT inventory. This system needs a reliable supply chain and precise demand forecasting. Timeliness is crucial. Any delays can stop the whole production process.

Quick Read: How “Just In Time Delivery” Becomes A Superhero With Supply Chain Visibility Software

Supply chain disruptions pushed manufacturers to focus on resilience. Businesses started to invest in new technologies like logistics management solutions. The rise of AI-driven workflows helped adapt to manufacturing complexities. Manufacturers also started using visibility tools to track inventory and predict disruptions. This helped manage supplier relationships and ensure timely delivery across the supply chain.

A survey by the National Association of Manufacturers (NAM) in 2024 found that 65% of manufacturers see attracting and retaining talent as their main challenge.

Download White Paper: Redefining Business Roadmap With Logistics Management Software

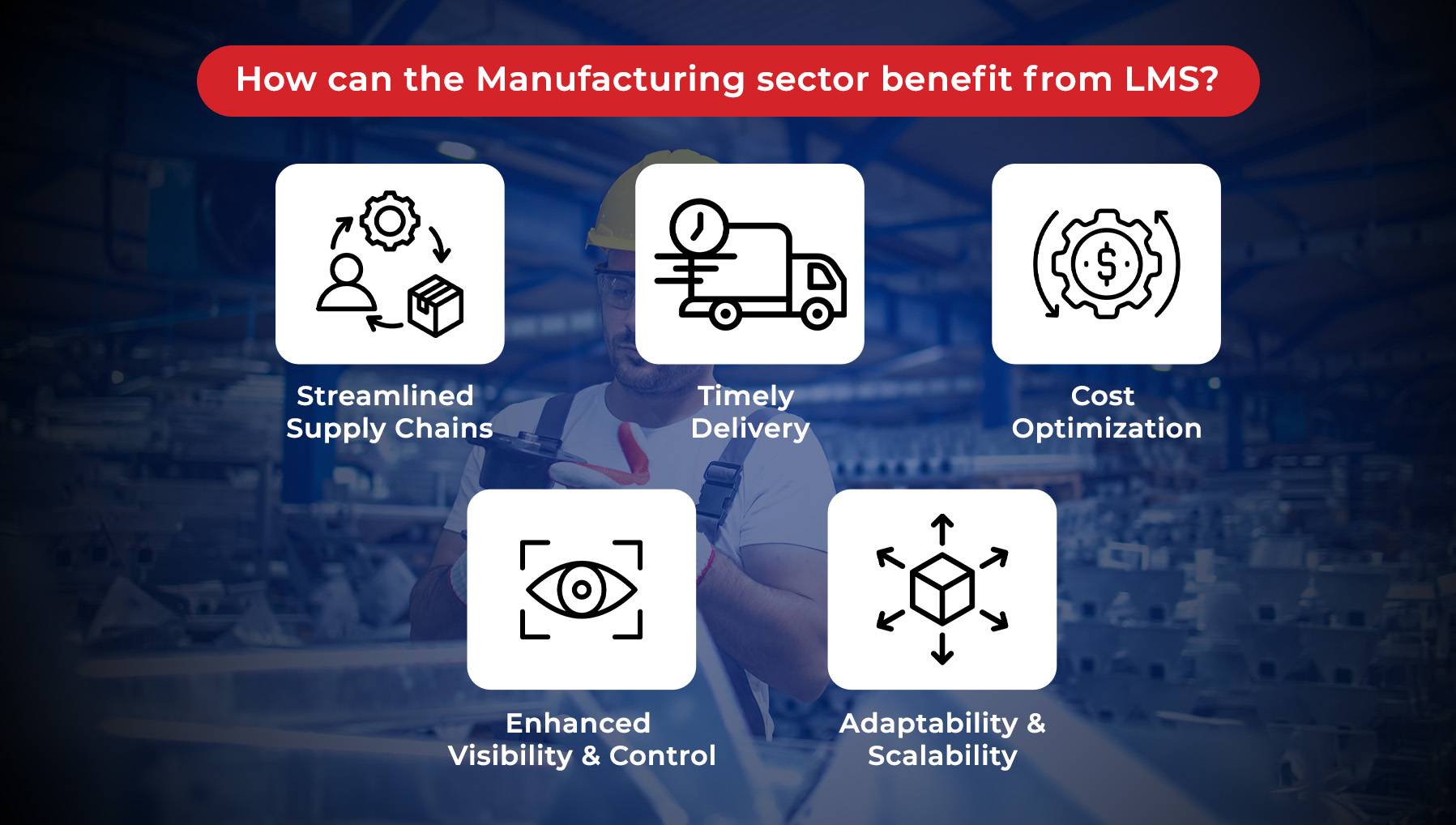

How can Investing in Technologies like Logistics Management Software Benefit the Manufacturing Sector?

Investing in logistics management software is crucial for boosting efficiency, productivity, and speed to market in the manufacturing sector. Here’s how this technology can revolutionize operations:

Streamlining Supply Chain Operations:

LMS enables manufacturers to streamline their supply chains by optimizing routes, reducing transit times, and minimizing costs associated with transportation and warehousing. Real-time tracking and monitoring capabilities ensure that materials and finished products move seamlessly from suppliers to customers, enhancing overall operational efficiency.

Timely Delivery Using Logistics Management System:

Meeting delivery deadlines is critical in manufacturing. Logistics management software facilitates accurate demand forecasting and efficient scheduling of transportation, ensuring that products reach customers on time. This capability enhances customer satisfaction and strengthens relationships with partners and distributors.

Best Logistics Management Software for Cost Optimization:

By optimizing logistics processes, manufacturers can reduce transportation costs, warehouse expenses, and operational inefficiencies. Advanced analytics within LMS can identify cost-saving opportunities, such as route optimization and load consolidation, ultimately leading to improved profitability.

Enhanced Visibility and Control for Logistics Management:

Visibility across the entire supply chain is essential for proactive decision-making. Logistics management software provides real-time insights into logistics operations, including shipment tracking, inventory status, and supplier performance. This visibility allows manufacturers to promptly address issues, mitigate risks, and capitalize on opportunities for continuous improvement.

Adaptability and Scalability With LMS:

In a dynamic manufacturing environment, flexibility and scalability are key to responding to changing market demands and business growth. LMS offers scalable solutions that can adapt to evolving needs, whether expanding into new markets or adjusting production volumes.

Don’t Miss: Top 7 Best Logistics Management Software Solutions

By investing in logistics management software, manufacturers can optimize their supply chains, improve operational efficiency, and maintain competitiveness in an increasingly demanding marketplace. This technology not only enhances productivity but also supports sustainable growth and customer satisfaction.

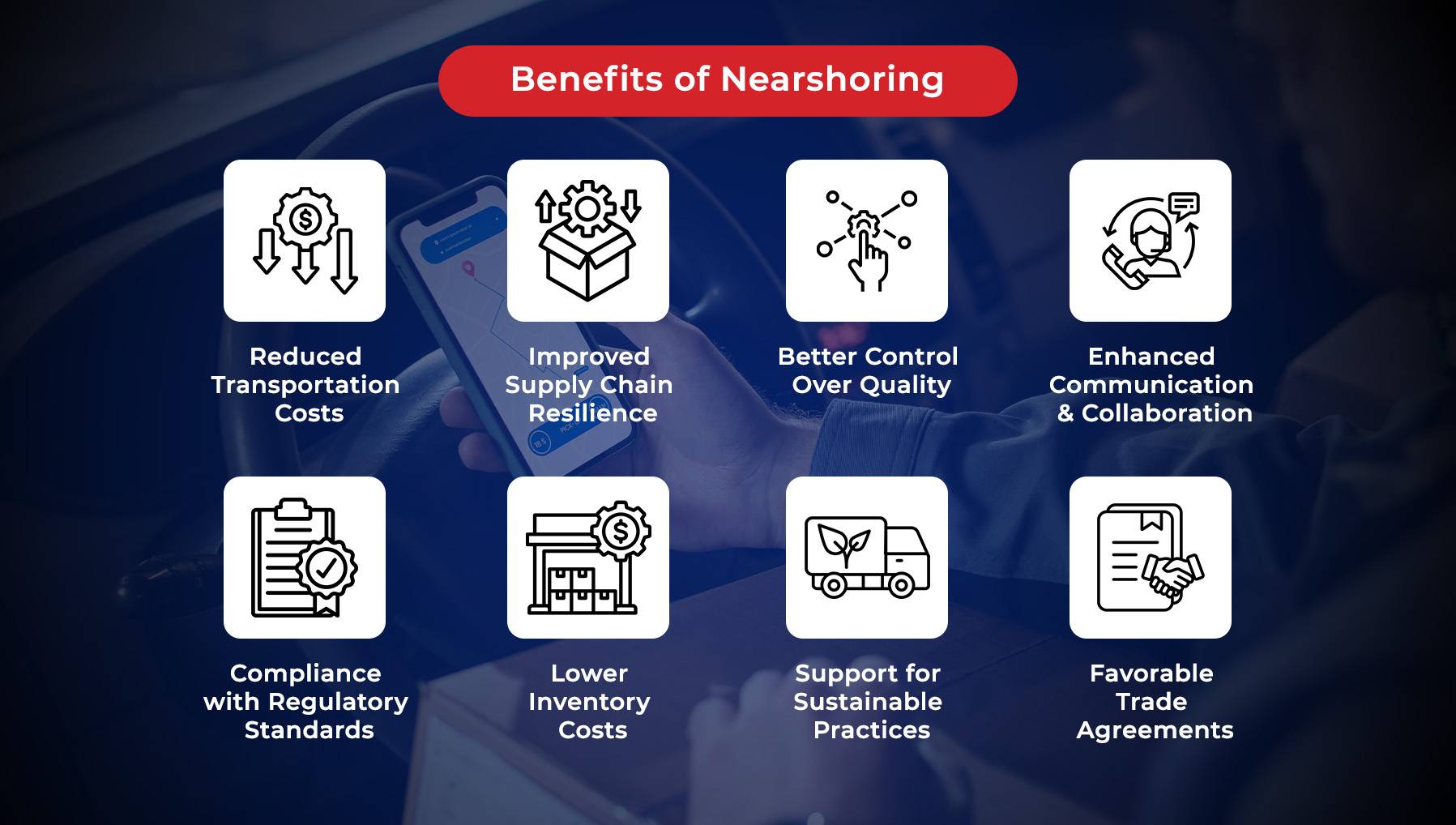

Nearshoring: A Strategic Shift in Manufacturing

Nearshoring is the practice of relocating production closer to end consumers. This trend has reshaped the manufacturing landscape, especially post-pandemic. During the COVID-19 crisis, many companies faced disruptions due to long supply chains. Nearshoring became a solution, reducing dependency on distant suppliers and bringing production closer to home.

Mexico has emerged as a key nearshoring destination. In 2023, Mexico exported $475.6 billion in goods to the U.S., a 4.6% increase from 2022. This shift is fueled by favorable trade terms under the United States-Mexico-Canada Agreement (USMCA) and increased foreign investment. U.S. car manufacturers have significantly influenced this trend, with 76% of the 3.5 million autos produced in Mexico each year exported to the U.S.

Logistics management software plays a crucial role in supporting nearshoring efforts. With LogiNext’s LMS, companies can gain better visibility into their supply chains. This software helps track, and manage transportation, and ensure timely deliveries. By optimizing operations, manufacturers can reduce costs and improve efficiency.

Nearshoring offers several benefits, including reduced transportation time, lower shipping costs, and improved supply chain resilience. However, managing these closer supply chains requires advanced tools and technologies. Our logistics management solution provides the necessary support to handle the complexities of nearshoring, ensuring a smooth and efficient manufacturing process.

Similar Read: Is Pop-Up Warehousing The Ultimate Fulfillment Centre?

How Can LogiNext Help the Manufacturing Sector with its Logistics Management Software?

Logistics management software plays a crucial role in supporting these changes. LogiNext’s LMS provides better visibility into supply chains, tracking and managing transportation, and ensuring timely deliveries. By optimizing operations, manufacturers can reduce costs and improve efficiency.

Discover: What Are The Best Logistics Management Software Tools And Techniques?

Nearshoring has become a strategic shift in manufacturing, with Mexico emerging as a key destination. Logistics management software supports nearshoring by providing the tools needed to manage closer supply chains. Our software offers the necessary support to handle the complexities of nearshoring, ensuring a smooth and efficient manufacturing process. This helps manufacturers reduce transportation time, lower shipping costs, and improve supply chain resilience.

By adopting advanced logistics management solutions like LogiNext, manufacturers can navigate the challenges of a rapidly changing market, stay competitive, and ensure their supply chains remain resilient and efficient. Click on the red button to book yourself a demo.

36

@LogiNext