Navigating Chinese New Year Logistics: Ensuring Supply Chain Resilience

Chinese New Year, also known as Lunar New Year or Spring Festival, has deep roots in Chinese culture and traditions. It marks the beginning of the lunar calendar and is celebrated with great fervor across East Asia and among Chinese communities worldwide. The festival originated from ancient agrarian societies’ practices of offering prayers for a good harvest and warding off evil spirits.

Chinese New Year festivities typically last 15 days, starting from the first day of the lunar calendar. During this time, families come together to honor their ancestors, share special meals, exchange gifts, and participate in various cultural activities such as dragon and lion dances, fireworks, and lantern festivals. Each day of the celebration holds specific customs and rituals, contributing to the rich tapestry of traditions associated with the holiday.

Also Read: 5 Tips To Cope-Up With Disruption In Global Supply Chain

Understanding the Impact of Chinese New Year on Logistics

Chinese New Year exerts a profound impact on global supply chains due to China’s pivotal role as the world’s manufacturing hub. As factories shut down for an extended holiday break, production and shipping activities come to a standstill, leading to disruptions in the flow of goods and materials worldwide. This disruption affects not only businesses directly linked to Chinese manufacturing but also those reliant on components and raw materials sourced from China.

Importance of Proactive Planning

The predictable nature of the Chinese New Year and its recurring impact on supply chain operations necessitates proactive planning.

– Planning ahead is essential for businesses to mitigate risks and maintain continuity during this period.

– Anticipating potential disruptions, implementing contingency measures, and collaborating closely with suppliers and logistics partners are crucial steps.

– Organizations can minimize the adverse effects of the holiday period by taking these proactive measures.

– Seamless operations throughout the festivities can be ensured by careful planning and proactive management strategies.

Also Read: Are You Prepared To Handle The Chinese New Year Online Order Surge?

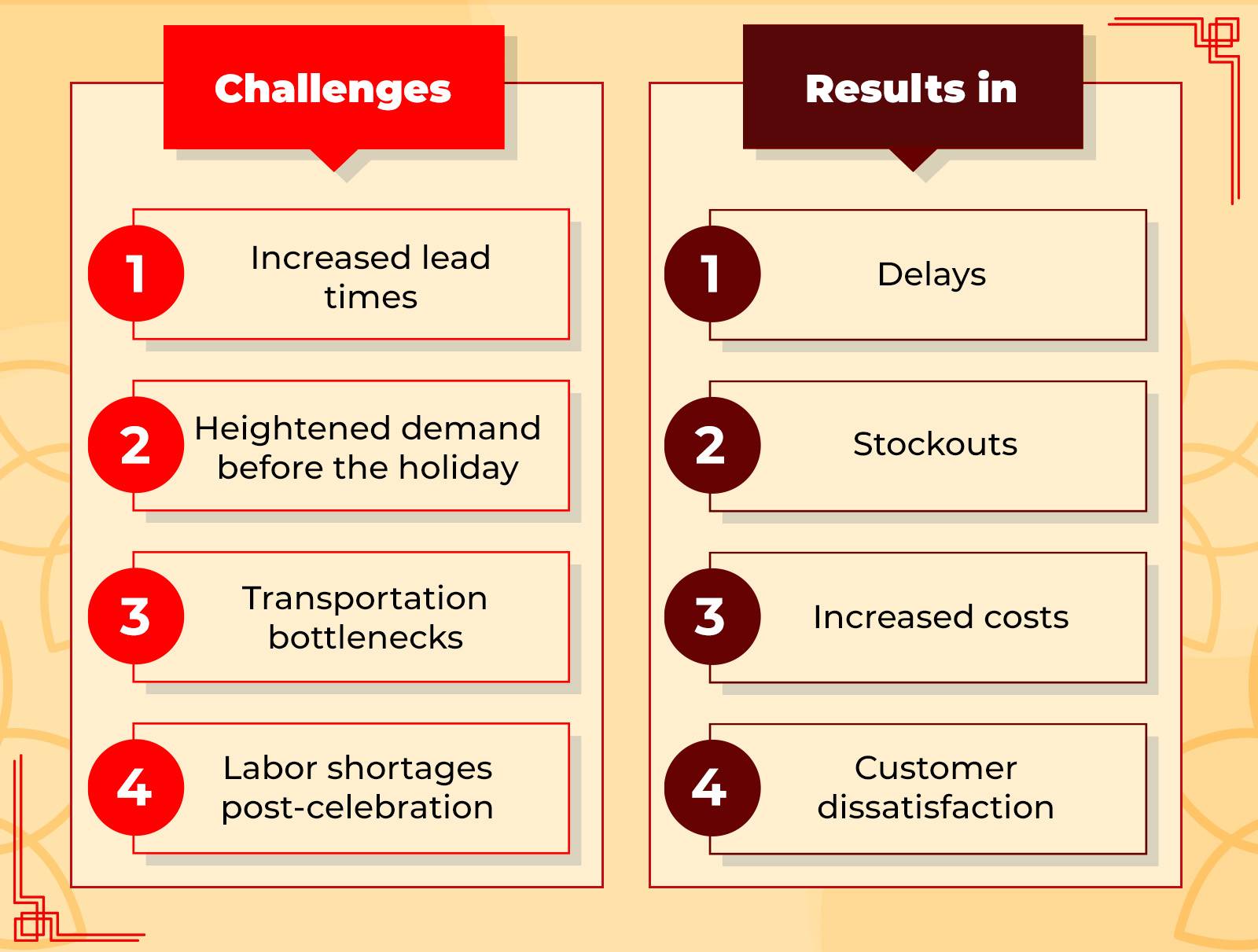

Challenges During the Chinese New Year

A. Increased Demand and Congestion

During the lead-up to Chinese New Year, there is typically a surge in consumer spending as people stock up on gifts, decorations, and festive goods. This spike in demand can strain logistics networks, leading to congestion at ports, warehouses, and distribution centers. As businesses rush to fulfill orders before the holiday shutdown, transportation capacities may be stretched thin, resulting in longer lead times, delivery delays, and higher freight costs. Additionally, heightened demand may exacerbate inventory shortages and stockouts, amplifying supply chain challenges for retailers and manufacturers alike.

B. Factory Shutdowns and Delays

One of the most significant challenges during Chinese New Year is the widespread closure of factories across China. As workers return to their hometowns to celebrate the holiday with their families, manufacturing operations halt for an extended period, typically lasting one to four weeks. This prolonged shutdown disrupts production schedules, delays order fulfillment, and interrupts the flow of goods within the supply chain. Moreover, factories may experience delays in ramping up production post-celebration due to labor shortages and logistical bottlenecks, further exacerbating the impact on supply chain efficiency and responsiveness.

C. Supply Chain Disruptions

Chinese New Year can trigger a cascade of supply chain disruptions across industries and geographies. From raw material suppliers to finished goods manufacturers to transportation providers, every link in the supply chain is susceptible to disruptions caused by the holiday festivities. Inventory levels may fluctuate unpredictably, leading to imbalances in supply and demand. Moreover, dependencies on single-source suppliers or concentrated manufacturing bases in China increase the vulnerability of supply chains to disruptions during this period. These disruptions can ripple through the entire supply chain, affecting production schedules, order fulfillment, and customer satisfaction for businesses operating in global markets.

Strategies for Supply Chain Resilience During Chinese New Year

A. Forecasting and Planning

Effective forecasting anticipates demand fluctuations, allowing for strategic inventory allocation and production scheduling, mitigating risks of stockouts and overstocking.

B. Diversification of Suppliers

Engaging multiple suppliers across regions reduces dependency on single sources, minimizing disruptions from factors like factory closures or transportation bottlenecks.

C. Inventory Management

Adopting agile inventory practices such as just-in-time replenishment and safety stock optimization ensures adequate inventory levels while minimizing holding costs.

D. Communication and Collaboration

Open communication and collaboration with suppliers, partners, and customers facilitate real-time information sharing, enabling swift responses to changing market conditions and disruptions.

Leveraging Logistics Management Software During Chinese New Year

Real-Time Visibility: Utilize logistics management software to gain real-time visibility into the movement of goods, allowing you to track shipments and monitor inventory levels throughout the holiday period.

Demand Forecasting: Leverage predictive analytics capabilities to forecast demand fluctuations during the Chinese New Year, enabling you to adjust inventory levels and production schedules accordingly.

Route Optimization: Use logistics management software to optimize transportation routes and schedules, minimizing transit times and reducing the impact of congestion and delays associated with the holiday period.

Communication and Collaboration: Enhance communication and collaboration with logistics partners and stakeholders by leveraging the communication tools and real-time data-sharing capabilities of logistics management software.

Performance Monitoring: Utilize logistics management software to monitor key performance indicators (KPIs) such as on-time delivery rates, inventory turnover, and transportation costs during Chinese New Year, allowing you to assess the effectiveness of your logistics operations and identify areas for improvement.

Dynamic Routing: Implement dynamic routing capabilities offered by logistics software to adapt to changing traffic conditions and congestion during Chinese New Year, ensuring efficient and timely delivery of goods despite disruptions in transportation networks.

Emergency Response Planning: Develop and implement emergency response plans using logistics software to mitigate the impact of unforeseen events such as natural disasters or geopolitical tensions that may coincide with Chinese New Year celebrations.

Collaborative Problem-Solving: Foster collaborative problem-solving among supply chain partners by leveraging the collaboration tools and data-sharing capabilities of logistics management software, enabling swift resolution of issues and disruptions during Chinese New Year.

Don’t Miss Out: Top Logistics Management Software For The Transportation And Logistics Industry

Conclusion

Importance of Proactive Logistics Management For Chinese New Year

Proactive logistics management is paramount for businesses to navigate the challenges posed by events like the Chinese New Year. By anticipating disruptions, optimizing processes, and fostering collaboration across the supply chain, companies can mitigate risks and maintain operational continuity. Investing in logistics management software not only minimizes the impact of disruptions but also enhances overall efficiency, responsiveness, and customer satisfaction.

Embracing Technology for Resilient Supply Chains During Festivities

Embracing technology, such as logistics management software, is essential for building resilient supply chains capable of withstanding disruptions like those encountered during the Chinese New Year. Advanced analytics, real-time visibility, and automation features offered by LogiNext empower businesses to make data-driven decisions, optimize processes, and mitigate risks effectively. By leveraging technology, companies can enhance supply chain agility, improve adaptability to changing market conditions, and position themselves for long-term success in today’s dynamic business environment. Click on the red button below to book a demo!

42

@LogiNext