Exception Configuration: The Silent Engine Behind High-Quality Deliveries

In modern supply chains, speed is no longer the competitive edge, control is. As parcel volumes surge and customer expectations tighten, logistics teams are discovering a hard truth: you cannot scale excellence if you cannot prevent errors. That is exactly why Exception Configuration has emerged as one of the most critical layers of logistics automation today.

It shifts logistics from reactive firefighting to proactive intervention, giving teams unprecedented command over operational quality. This is the difference between hoping things go right and engineering them to.

The Harsh Reality on the Ground

Everyone in operations knows this: issues don’t show up politely on dashboards. They erupt in real warehouses and on real delivery routes.

A few examples from day-to-day experience:

– A box arrives with a dent. No one flags it.

– Driver scans a parcel out of sequence.

– Rider takes the wrong lane and heads towards the wrong hub.

– A package weighs more than the manifest mentions.

– Barcode doesn’t match the assigned route.

These incidents may seem tiny but they happen every minute in any high-velocity logistics operation. And in most networks, these errors quietly slip through. They hide inside spreadsheets, in rushed handovers, or in someone’s mental notes that inevitably get lost.

The result? Mistakes get discovered only when someone downstream, usually the customer, raises a hand and asks, “Where’s my order?”

By then:

– Delivery timelines have already collapsed.

– Agents scramble to trace the shipping exception.

– Managers dive into calls to calm customers.

– Teams waste hours in reactive investigation.

Multiply this across thousands of daily orders, and the cost of missed logistics exception handling becomes astronomical, lost revenue, wasted time, brand damage, and operational fatigue.

This is the exact gap LogiNext solves with structured logistics exceptions automation.

What Happens Without Logistics Exception Automation

Let’s call it what it is: chaos disguised as process. Without a system like LogiNext:

– Exceptions depend on memory, not intelligence.

– Shipping exception data gets siloed across teams.

– Delivery exception events go unnoticed until too late.

– Misroutes require manual review.

– Damaged parcels get processed incorrectly.

– SLA failures become “unavoidable realities”.

In short, logistics teams rely on short-term fixes instead of long-term control.

And in CEP, e-commerce, and retail logistics, this is a recipe for unpredictable costs. Studies show that 25% of delivery delays originate from untracked or unmanaged exceptions. Another 19% of customer escalations come from basic errors that could have been prevented at source.

That’s why leading enterprises are investing heavily in logistics automation that catches problems the moment they occur, not hours later.

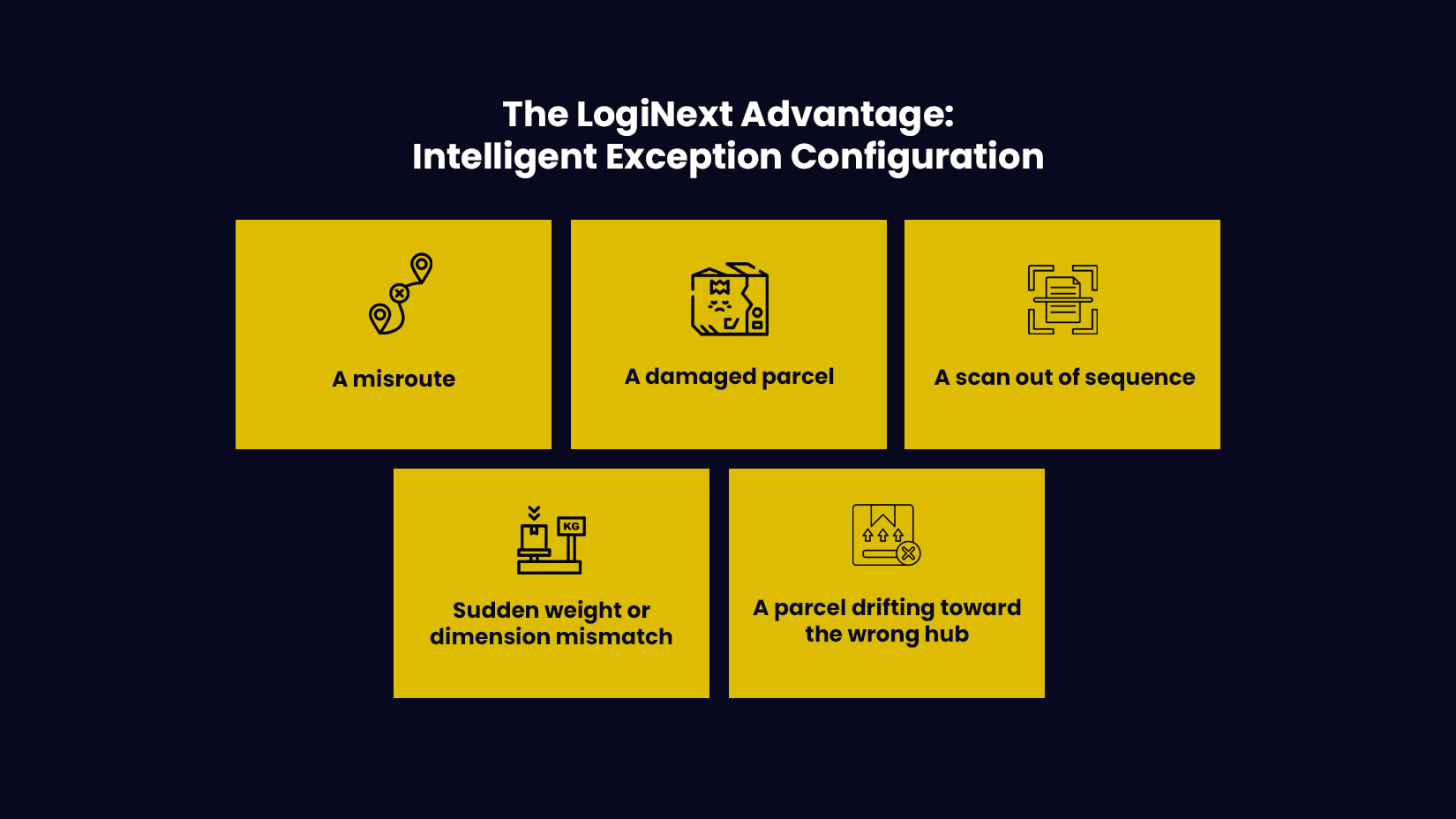

The LogiNext Advantage: Intelligent Exception Configuration

This is where LogiNext changes the game. The system doesn’t wait for someone to notice an issue. It identifies, classifies, and triggers actions the instant a logistics exception occurs.

Here’s how it works:

1. A misroute?

LogiNext blocks it immediately and reassigns the parcel to the correct path, no manual lookup, no back-and-forth messages.

2. A damaged parcel?

The system alerts the right team, surfaces the SOP, and ensures the issue is recorded, validated, and resolved efficiently.

3. A scan out of sequence?

The driver receives a real-time prompt to correct the flow and avoid an unnecessary delivery exception.

4. Sudden weight or dimension mismatch?

Instant classification, automated approval workflows, and cost accuracy restored.

5. A parcel drifting toward the wrong hub?

Dynamic geofencing detects the deviation and triggers alerts before it becomes a failure.

Every one of these issues becomes a guided micro-workflow, documented, trackable, and measurable. That’s the power of structured exception handling within end-to-end logistics automation.

Why This Matters: The Business Value of Exception Configuration

Most logistics leaders underestimate exceptions until they see the numbers. Across our CEP and retail clients, LogiNext’s logistics exceptions automation has delivered:

– Up to 70% faster exception resolution.

– Up to 40% fewer missed scans and operational errors.

– Over 30% reduction in customer escalations.

– Higher SLA compliance (up to 15% improvement).

– More predictable delivery costs.

– Fewer reattempts and return-to-origin (RTO) events.

In some cases, clients have saved 10% of operational costs simply by controlling exceptions more intelligently. And while this number varies depending on the parcel value and operational scale, the trend is clear: early detection prevents the financial bleed that occurs later in the chain.

Exception Configuration becomes the heartbeat of high-quality execution.

Turning Chaos Into Control

Let’s be honest: exceptions will never disappear entirely. Logistics is a physical business with moving parts, weather, people, machinery, and a hundred variables you cannot fully control.

But what you can control is:

– How fast you detect the issue

– How clearly you classify it

– Resolving it efficiently

– Consistently preventing it next time

This is precisely what automated shipping exception management enables.

When every logistics exception is captured in real time and tied to a clear workflow:

– Branches stay aligned

– Operations teams stay ahead

– Managers gain unprecedented visibility

– Customers never feel the turbulence behind the scenes

You transform logistics from a reactive cost center into a proactive quality engine.

Logistics Automation Isn’t Just a Technology Upgrade, It’s an Operating Philosophy

Enterprises often focus heavily on routing, tracking, or capacity planning. But the smartest operators understand that routing alone doesn’t guarantee success. What guarantees success is controlling what goes wrong.

This is why Exception Configuration is quickly becoming a non-negotiable layer in modern logistics automation strategies:

– It reduces dependency on manual monitoring

– Increases network reliability

– Cuts down SLA penalties

– It protects margins

– Strengthens customer trust

– It allows teams to scale operations without scaling chaos

It’s the invisible guardrail that ensures every delivery meets the promise made at checkout.

Also Read: LogiNext Wins “Best TMS Platform of the Year 2026”: A Milestone for Global Logistics Innovation

Conclusion

In high-velocity logistics, perfection is a fantasy but precision is very real. Exception Configuration is what brings that precision to every parcel, every shift, every route. By turning every exception into a guided, auditable micro-workflow, operations move from scrambling to steering. The result? Fewer errors, faster resolution, and a noticeable lift in customer trust, because the system doesn’t wait for things to break before stepping in.

This is logistics automation at its sharpest: quiet, powerful, and relentlessly effective. When you control exceptions, you control outcomes and that’s how you protect your delivery promise every single day. Want to see how LogiNext does it in the real world? Click on the red button and experience exception-proof logistics firsthand.

27

@LogiNext