Inbound Logistics Software: The Essential Guide

Getting the inbound logistics right is no longer a nice-to-have. It is a must-have that provides the backbone for predictable supply chains. And that’s where inbound logistics software comes in, providing control, visibility, and data-driven decisions without forcing teams to wrestle with museum-like spreadsheets. With today’s turbulent demand, variability, and soaring transportation costs, businesses have begun to tighten their grip on each inbound shipment.

This guide explains what it is, why it matters. And how the right tool transforms procurement, storage, and coordination with suppliers.

What Is Inbound Logistics Software?

Inbound logistics software is a digitized system that supports the organization in planning, managing, and tracking all activities involved in bringing goods from suppliers into their operations. Think of it like an intelligent command center streamlining supplier coordination, automating tedious checks, and providing real-time visibility over shipments.

Modern supply chains are complex. A typical mid-to-large enterprise manages between 50 to 300 active suppliers and handles thousands of inbound shipments per month. Without technology, errors pile up fast—late shipment, quantity mismatch, stockouts, or even worse, paying for goods that never arrived.

An inbound logistics system solves these problems by centralizing data, automating workflows, and giving teams the ability to act before a problem is costly.

Key Features of Inbound Logistics Software

A well-designed inbound logistics solution does more than track shipments: it keeps your suppliers accountable and your teams informed.

1. Supplier Collaboration Hub:

Suppliers get a centralized portal to upload documents, confirm ETAs, share shipment updates, and flag delays early. This reduces dependency on e-mail threads and scattered communication. Teams have a single source of truth for the confirmation of orders, checks of quality, and compliance requirements. The result is faster coordination and fewer last-minute surprises.

2. Real-Time Shipment Tracking:

GPS visibility, EDI updates, and predictive ETAs make sure teams always know where inbound goods are. This decreases guesswork, production downtime, and helps drive proactive decisions. On average, these systems improve the accuracy of ETAs up to 35%, keeping businesses precise with receiving, labor, and dock operations planning.

3. Automated Check-Ins and Receiving:

Scanning of barcodes, matching of ASNs, and automatic generation of GRNs reduce the occurrence of manual errors by up to 80%. These tools accelerate receiving, eliminate paperwork, and ensure each shipment is validated instantly.

4. Dock & Yard Scheduling:

Inbound bottlenecks can cost hours. Smart scheduling assigns the dock slots based on ETAs, vehicle type, load size, and priority. This improves utilization at the dock by 25-40% and minimizes congestion.

5. Advanced Analytics:

The best of these platforms go beyond reporting. Predictive dashboards that highlight patterns in supplier delays, lead-time inconsistencies, and cost leakages set businesses up with insights to support continuous improvement and strategic sourcing decisions.

Benefits of Using Inbound Logistics Software

Here’s where the transformation begins. When companies deploy inbound logistics management software, the ripple effect touches everything from procurement to warehousing and finance to customer satisfaction.

1. Reduced Costs:

Better inbound planning cuts hidden inefficiencies-like expedited freight, safety stock, supplier errors, and delays that demand costly workarounds. Organizations often reduce inbound transportation and handling expenses by 12-18%, while also lowering inventory carrying costs through tighter lead-time control.

2. Greater Supplier Accountability:

With open data, performance metrics, and auto-generated scorecards, suppliers can no longer blur updates. Companies are better equipped to ensure SLAs are met, negotiate on a more equal footing, and ensure consistent supply reliability.

3. Fewer Stockouts and Production Delays:

Predictive ETAs and real-time alerts make sure teams can react before the disruption hits. This stabilizes production lines, protects service levels, and reduces the cascading costs of downtime.

4. Stronger Inventory Accuracy:

Automation of ASN validation, scanning of barcodes, and system-driven receiving reduces manual errors by as much as 80%, improving end-to-end inventory accuracy.

5. Faster Receiving Operations:

Digitized workflows accelerate unloading, validation, and putaway. Most warehouses increase receiving efficiency by a range of 40–60%, freeing labor for higher-value tasks.

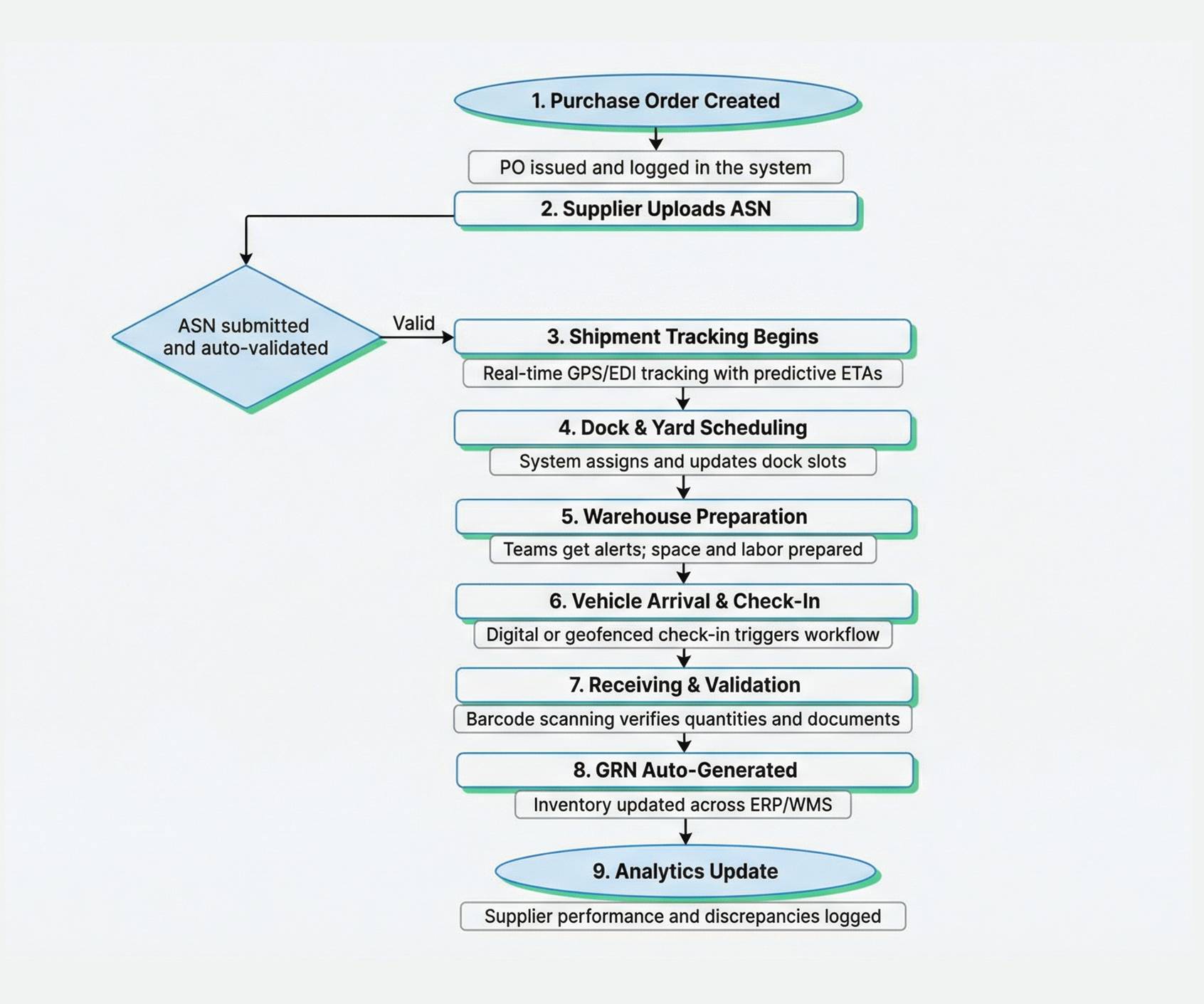

How an Inbound Logistics System Works

An inbound logistics system smoothens out every step in the trip from supplier to warehouse. Before the flowchart goes into detail, here’s an overview. This process connects suppliers, transporters, and the warehouse teams on one integrated platform to ensure accuracy, visibility, and timely inbound movement.

This structured flow ensures every inbound shipment moves with precision-from ASN creation to the final inventory update. With automation and real-time intelligence built in, the whole process becomes faster, more predictable, and far easier to manage at scale.

Who Needs Inbound Logistics Software?

Not just global giants, any organization dealing with high volumes of inbound or supplier complexity benefits from an inbound logistics solution.

Key industries adopting it fast:

– Retail & FMCG.

– Manufacturing.

– Pharmaceuticals.

– Automative.

– E-commerce & 3PLs

– Consumer Electronics.

– Food & Beverage.

Basically, if inbound delays hurt your customer commitments, this software lands right in your strike zone.

Challenges of Managing Inbound Logistics Manually

If you are still using spreadsheets and emails, then these issues probably feel too familiar:

1. Invisible Delays:

Manual tracking means updates arrive late, inconsistent, or not at all. Teams often learn about shipment issues only after they cause production or inventory disruptions. Without predictive insight, businesses remain perpetually reactive rather than proactive.

2. Overloaded Docks:

Without coordinated scheduling, various suppliers send in trucks at the same time, which leads to congestion, idle labor, and slower turnarounds. The outcome is bottlenecks that ripple across warehouse operations.

3. Vendor Miscommunication:

Relying on emails and calls heightens the risk of missed updates, outdated ETAs, and unclear responsibilities. One misalignment can stall entire workflows.

4. Paper-Based Receiving:

Paper forms slow down teams, increase human errors, and make audits painful. Lost documents or mismatched records often result in disputes, delays, and inaccurate inventory.

5. Poor Forecasting:

Scattered data limits the view of inbound trends, supplier performance, and lead-time variability. Planners cannot accurately forecast demand; hence, stockouts and excess inventory levels lead to higher carrying costs.

Also Read: What Is Logistics Software? The Part of Your Business That Does the Adulting

Final Thoughts

Inbound logistics isn’t glamorous, but it’s the engine room of every business. And when you start to rein in inbound, everything else-inventory, production, order fulfillment-starts to run more smoothly. Finally, with inbound logistics software, organizations get the visibility, predictability, and efficiency that spreadsheets just can’t provide.

This is the time to modernize. Because, in a world where delays cost millions, the right inbound logistics solution isn’t an upgrade-it’s a competitive shield. So, do not delay and book a demo with LogiNext Solutions. Click on the red button to know more.

32

@LogiNext