In a Volatile World, Logistics Becomes the Supply Chain Anchor

This age is marked by geopolitical turbulence, changing tariffs and rapidly swinging consumer patterns. Supply chain management is no longer a backstage concern, logistics and fulfillment are now the center stage. Companies are now crawling to build resilience, and adopting a smart logistics software has become a mandate of that effort.

Why Volatility Has Put Logistics in the Spotlight

For a number of enterprises today, the classic supply chain is under duress. Uncertainty in trade policies, shipping delays and erratic demand spikes makes the traditional models fragile. Clients today are increasingly focused on how technology can help them weather these shocks.

Specifically, shippers are not only asking whether parcel freight and less-than-truckload (LTL) are still the best options for them. They are asking, if full-truckload (FTL) might now offer a more reliable and efficient path forward.

The Rise of FTL Freight: A Reflection of Risk Appetite

Volatility is driving a surprising shift: FTL is growing faster than LTL. A research by Forrester shows that:

– FTL is taking a greater share because of its speed and predictability, one movement from origin to destination creates less handling and risk.

– It reduces the risk of damage and delay because goods are only loaded and unloaded once.

– LTL is becoming more complicated and costly: driver shortages, congested terminals, and overhead of coordination make LTL less desirable.

As businesses grow, they frequently transition from LTL to FTL because the volumes justify the switch.

This shift is about more than just freight types. It also shows how logistics management software (transportation management systems in particular) can be used to reduce friction on FTL shipments.

Technology as the Great Equalizer

Volatility, demands a technology that brings control, visibility and agility. Here is how the companies are using logistics management solutions to stay ahead of the competition:

1. Real-Time Visibility & Tracking:

Using IoT, GPS, and telematics, organizations are monitoring FTL (full truckload) shipments in real-time. This is specially for high-value goods or time-sensitive loads.

2. On-Demand Freight Market Places:

Freight marketplaces, such as Uber Freight and Convoy, allow companies to compare rates, check capacity, and book freight delivery directly through a software system.

3. Route Optimization & Dynamic Scheduling:

AI-powered technologies process traffic, weather, and road conditions. This helps to plan the most efficient routes through a software platform, which saves time and money.

4. Predictive Analytics & Demand Forecasting:

Machine learning models predict surges or lulls in demand. Thereby, assisting firms in determining the right time to combine loads, switch freight modes, or decide fulfillment strategies.

5. Automation & System Integration:

APIs and cloud-based systems (e.g. TMS and WMS) automate pickups, customs clearances, and load management.

These tools are part of a broader software ecosystem for managing the supply chain. They improve the ability for companies to respond to changes quickly and to maintain control even under uncertain circumstances.

Managing Trade Volatility: Technology to the Rescue

Supply chain leaders are constantly dealing with trade volatility caused by tariff changes, geopolitical risks, and changes in manufacturing footprints. Some companies use their own digital solutions to minimize risk, instead of relying solely on freight forwarders, they insource fulfillment.

Digital customs portals, as well as in-transit tracking and digital measurement, allow a company to have their own transportation and storage contracts, to handle customs declarations and settlements, among other tasks. This represents a significant step toward independence and responsiveness.

However, the decision to insource is not easy. As one analyst put it, whether or not a company should insource is dependent upon their core value proposition:

Compete on price? Outsource. Pool resources with others to spread fixed costs.

Compete on service? Insource. Control logistics by investing in TMS, WMS, or other logistics programs to create manage the customer experience.

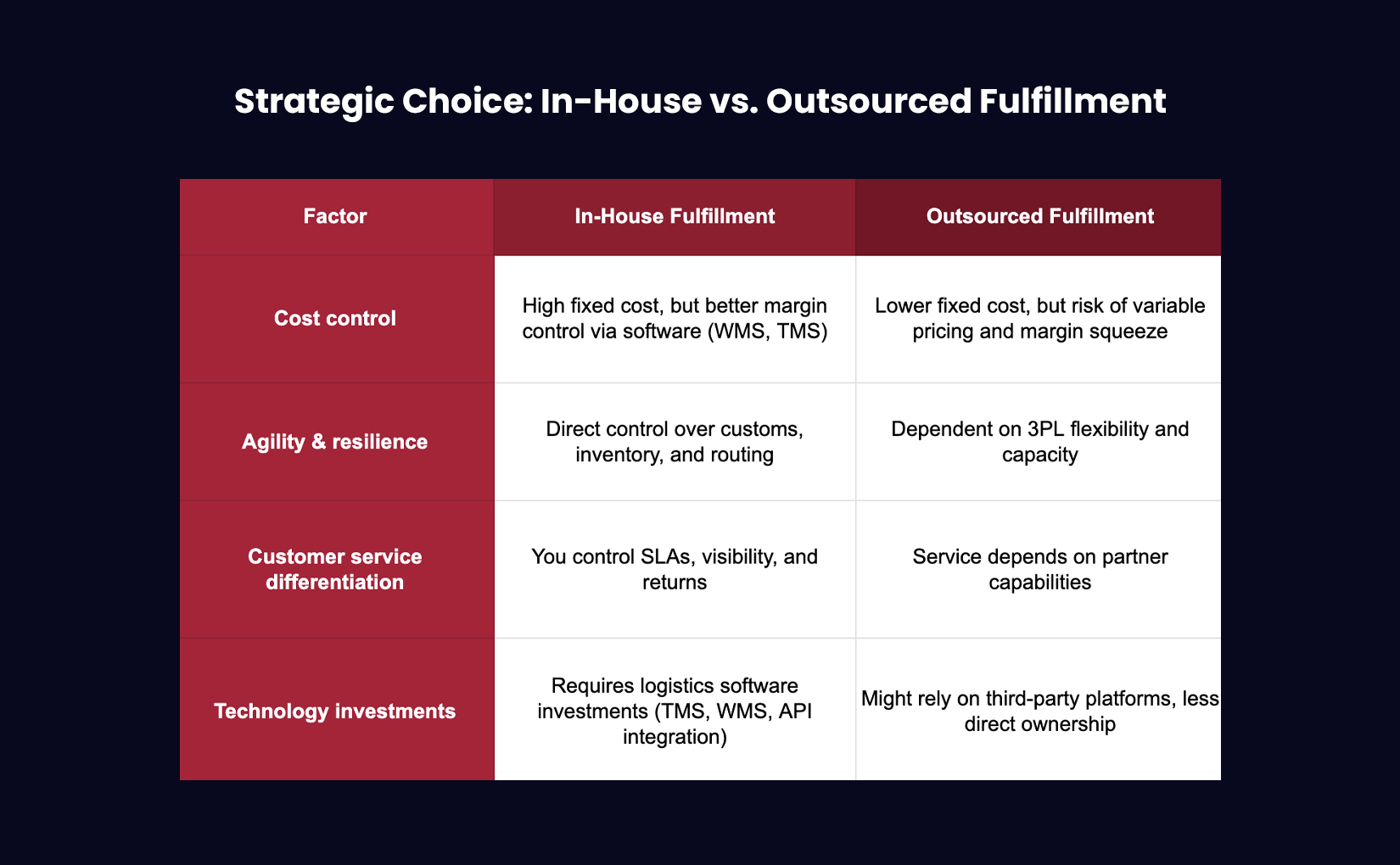

Strategic Choice: In-House vs. Outsourced Fulfillment

Deciding whether to shift fulfillment in-house or to use third parties is one of the biggest logistics gambles that companies are making right now. Here are some good considerations:

The decision is not entirely economic in nature, it’s strategic in nature. When markets are volatile, the companies that win on service typically manage their logistics operations themselves. And have visibility and planning, utilizing supply chain management software, to back it up.

Why Logistics and Fulfillment Are Now Boardroom Priorities

Logistics was very much a back-office function, a necessary cost in previous years. Now, in a time of volatility, it is thought of as a front-line weapon in competitive differentiation. When customers are experiencing delays or shortages, rapid delivery based on real-time tracking is a competitive advantage.

Companies can incorporate logistics management solutions, like TMS and WMS software, across their operational processes. It strengthens the resilience of supply chain management systems. That move complements that of reacting – anticipating, optimizing, and future-proofing supply chain systems.

How to Choose the Right Logistics Software Strategy

Here are actionable steps for organizations looking to improve their logistics capabilities during tumultuous times:

1. Map Your Risk Exposure:

Identify key trade lanes, tariff-exposed flows, and products that are sensitive to time.

2. Audit Your Technology Stack:

Do you have a transportation management system (TMS), a warehouse management system (WMS), or a broader logistics management solution? If so, where are there gaps?

3. Model In-House vs. Outsourced Scenarios:

Run cost-benefit scenarios: What is total cost of ownership for in-source with software? What sort of flexibility do 3PL’s offer?

4. Partner for Visibility:

Invest in supply chain management software that gives you real time visibility, or find a 3PL who has it as part of their bundle.

5. Build Predictive Capabilities:

Use tools to analyze analytics and machine learning to help predict demand surges, optimize freight and conduct dynamic routing of shipments.

6. Iterate, Don’t Flip the Switch:

Start small. Pilot in a region or a product line. Measure outcomes. Scale up based on results.

Final Thoughts

Supply chain volatility is now a standard part of our operations, rather than an anomaly. In that reality, logistics and fulfillment are no longer the unsung heroes. They manifest as the engines of the full show. Teams that invest in logistics software and broader-scale supply chain management software not only survive loss of predictability but turn that into momentum.

Owning fulfillment – regardless if that is in-house or with trusted partners – gives supply chain companies the resilience and agility outstanding companies want and demand within today’s market. Not only does this keep the delivery timeline on point. But it reduces customer concerns and keeps them engaged and excited through operations beyond one development to the next. If you’re ready to get control of the chaos – book a demo with LogiNext and see what the right logistics management solution means for competitive advantage.

22

@LogiNext