Logistics Regression Software: What It Actually Does

The logistics industry incorporates numerous moving parts—again, quite literally. The logistics industry includes trucks, drivers, warehouse staff, orders, fuel costs, delays, weather, shifts in the market. Along with these it also includes, the customer whose expectations seem to stretch each quarter. As a result, when operating in the logistics world, making decisions without the aid of logistics regression software can quickly lead to guesswork. When combining one’s intuition and outdated spreadsheets, business can become inefficient, have late deliveries, and unnecessary costs.

Logistics regression software offers a companies a data-driven tool to know trends, forecast results and make smarter operational decisions. However, let’s get beyond the jargon, and keep it real: even so many companies still do not understand what logistics regression software does, or more importantly, why they should even care. Let’s break it down in a simplistic way, shall we?

What Is Logistics Regression Software?

Logistics regression software leverages logistic regression models to determine the likelihood of specific scenarios occurring within a logistics ecosystem. It acts as a knowledge engine by stating:

– Which deliveries may be late.

– Routes may be more expensive than anticipated.

– Which drivers might need to be reassigned.

– Which inventory status could soon become a problem.

Rather than responding to issues in the wake of disruptions to operations, the software enables logistics organizations to predict and prevent issues from happening. In other words – it is purposeful forecasting.

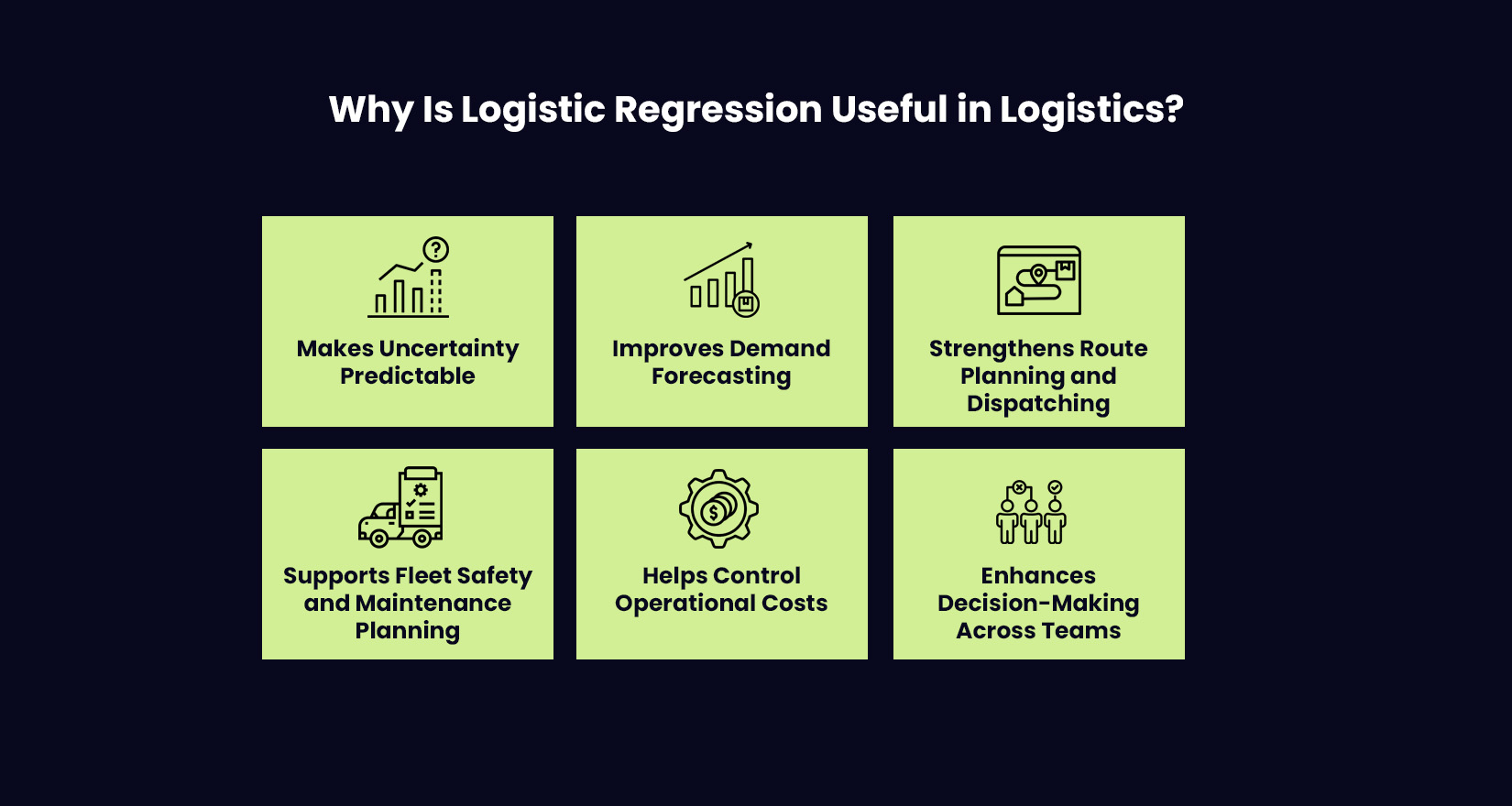

Why Is Logistic Regression Useful in Logistics?

1. Makes Uncertainty Predictable:

Logistics involves a myriad of variables—road, weather, fuel prices, demand fluctuations, delayed spinners, etc. Logistic regression assists in quantifying these variables on outcomes. Rather than reactively respond to surprises as they arise, teams can predict what disruption may occur prior to the event.

2. Improves Demand Forecasting:

The model uses historical sales patterns, seasonal demand patterns, and consumer behavior to assess the probabilities of stock-outs or excess inventory purchasing for restocking. Good demand planning will minimize the occurrence of last-minute emergency replenishments causing unhappy customers.

3. Strengthens Route Planning and Dispatching:

Logistic regression can assess the likelihood a delivery will be delayed. It is based on route history, data around driver performance, and congestion levels on the route. This results in improved knowledge for planning routes allocating deliveries to trucks, better estimated time of arrivals(ETAs), and less operational worry.

4. Supports Fleet Safety and Maintenance Planning:

Historical driver behavior, engine performance data, and usage patterns allow for the ability to forecast risks like accidents or breakdowns. This enables preventive maintenance schedules instead of expensive last-minute fixes.

5. Helps Control Operational Costs:

The software allows your team to identify where, and to what extent, inefficiency exists, fuel consumption, idle time, hours in labor, the path for decreased or eliminated waste is clearer. Predictive cost modeling will help forecast business costs and drive tighter budgets and margins.

6. Enhances Decision-Making Across Teams:

Probability-based insight prevents managers from making decisions solely based on gut instinct. Logistics regression allows planners, dispatchers, and warehouse supervisors to implement set of rules. Also, take faster, more confident actions based on good data.

What Does a Logistics Regression System Actually Do?

Logistics regression enables you to transform your operational data into foresights for more informed decision-making. Rather than providing only a historical record of actions taken, it allows you to predict upcoming actions and understand how to react to those predictions.

1. Centralizes Your Logistics Data:

Often, logistics teams are attempting to manage data coming from TMS, WMS, ERP, Telematics, and customer data systems. Software brings all of those data points together in one centralized location. The result is a single set of organized data that eliminates confusion, reduces manual tracking and speeds decision making.

2. Detects Patterns and Predicts Outcomes:

The system looks through both historical and immediate data to see what ‘drives’ the outcome you achieved; such as delivery delays, or fuel price spikes or stock-outs. It will compute what the probability is of experiencing those outcomes in the future. This moves your operations from responding to the problem, to avoiding those problems altogether.

3. Suggests the Best Next Actions:

The system not only provides predicted outcomes, it also recommends actions. For example, it may recommend to change the route, or modify the driver assignment, or even to stock earlier than planned. The predictions are timely and relevant to actions you can take. But the recommendation also provides an additional level of data-based confidence to help your teams act quickly and effectively.

Use Cases: Where It Helps Most

1. Last Mile Delivery:

The last mile comprises 53% of the total shipping cost and every unsuccessful delivery costs an average of $17 to recover. Logistics regression software works to anticipate delays from traffic, address errors, and driver inefficiencies. Thereby, resulting in smoother routes and improved first-attempt success rates.

2. Fleet Management:

Unanticipated maintenance is 3-9x more costly than scheduled maintenance. By examining driver and vehicle data, logistics regression software can predict the risk of breakdowns as well as spikes in fuel in advance. This translates into constant fleet performance without unplanned costs.

3. Inventory & Demand Forecasting:

Inventory holding costs are 20-30% of the total inventory value, and 34% of customers will switch brands if they find the item out of stock. Accurate forecasts are the first step to avoiding both over- and under-stocking. And also staying in the logistics Goldilocks zone of inventory exactly when you need it, and just enough of it.

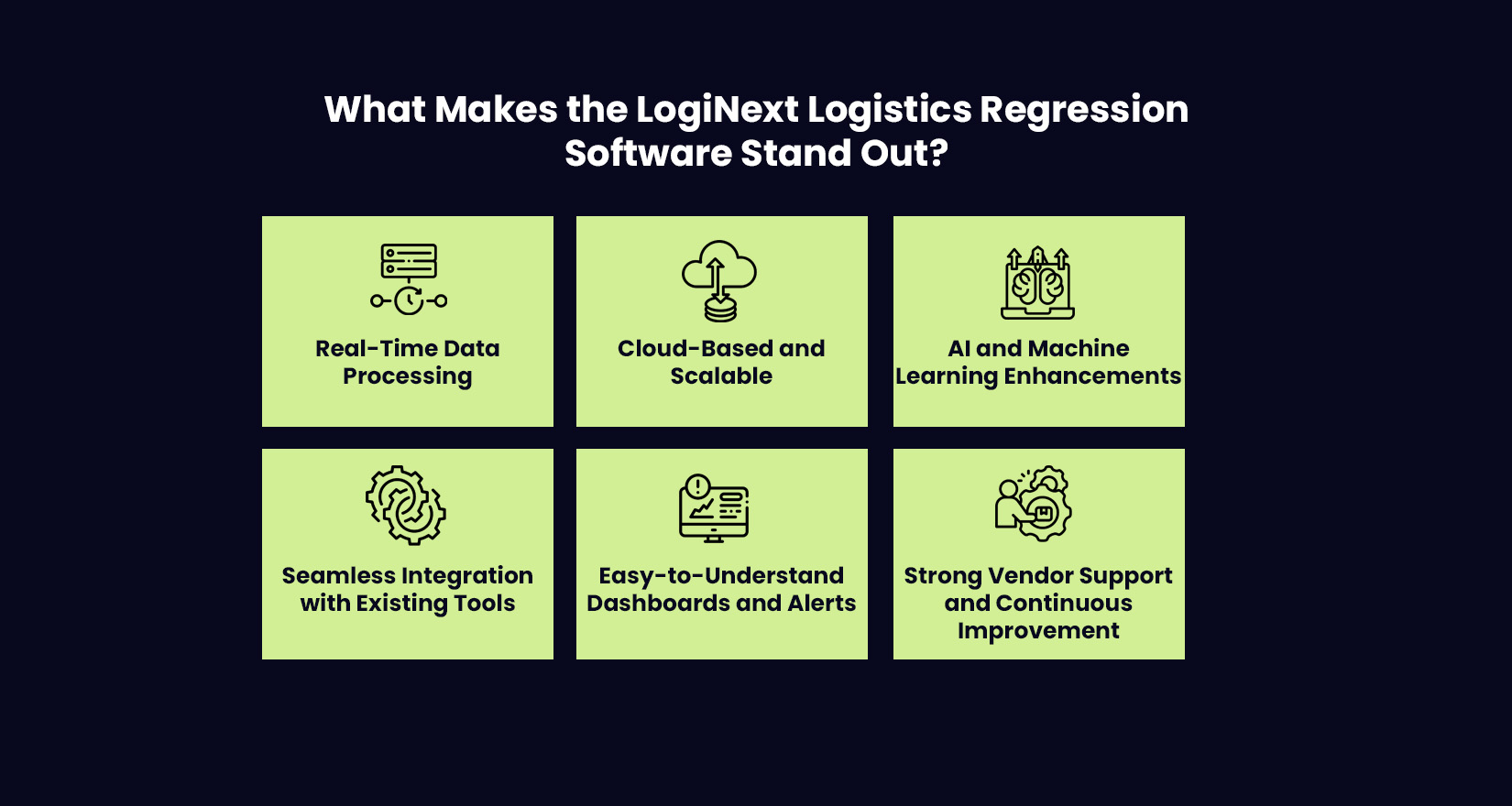

What Makes the LogiNext Logistics Regression Software Stand Out?

1. Real-Time Data Processing:

A good logistics regression solution is scalable and will grow as your business grows. Whether you are operating in one region or across all continents the best logistics regression platform should scale with ease. A cloud-based systems are easier to deploy, maintain and upgrade, and easier to deploy and update for remote and multi-location collaboration.

2. Cloud-Based and Scalable:

A good logistics regression solution is scalable and will grow as your business grows. Whether you are operating in one region or across all continents the best logistics regression platform should scale with ease. A cloud-based systems are easier to deploy, maintain and upgrade, and easier to deploy and update for remote and multi-location collaboration.

3. AI and Machine Learning Enhancements:

The best logistics regression system doesn’t just compute, it also learns. The system will become more accurate due to the continual training of the models. The patterns will become more detailed as predictions improve, and those predictions will be increasingly accurate as the system continues to learn autonomously as operational behavior changes.

4. Seamless Integration with Existing Tools:

Software that requires you to change your entire stack is not worth considering. The best solutions easily plug into your TMS, WMS, ERP, stacks, fleet tools, GPS devices, and consumer interfaces. You won’t lose time migrating, and you avoid clunky legacy transfers where data is moved but then dissimilar in structure.

5. Easy-to-Understand Dashboard and Alerts:

Data for data’s sake is useless unless people can read it. The best performing software has easy to understand dashboards, visual analytics, and real-time alerts. Your teams do not need to be data scientists to make sense of insights they receive regularly when they need the information.

6. Strong Vendor Support and Continuous Improvement:

The logistics industry changes rapidly, and any software should change with it. The best logistics software is connected to vendors that support you ongoing commitment but provide updates frequently, and share the future roadmap. If the system stops evolving, you won’t either.

Also Read: What Is Logistics Software? The Part of Your Business That Does the Adulting

Conclusion

Logistics regression software isn’t just something you read in textbooks. It is a useful, practical tool that supports logistics teams in getting beyond putting out fires to data-driven decision making and proactive planning. Rather than reacting to issues once they have caused disruption, the system provides the team with visibility into the future. It explains the current state with respect to why it is happening? And how to work towards mitigating the impact before it financially hits the business.

Companies that begin building predictive logistics models today, will be able to take the leadership role into the future and kick start the industry cycle into the future. Those who choose not to take action will be left behind as a cautionary tale of inefficiencies and missed opportunities. If you want to make the jump from defense to offense, and put the intelligence piece into your logistics strategy, book a demo with LogiNext to see where the future can begin.

56

@LogiNext