Predictive Analytics in Logistics Software: Smarter Planning for the Future

No longer is logistics simply about transporting products from point A to point B. The real challenge in the fast-paced economy is not only the unexpected disruption. Its the availability of the proper resources, and controlling costs, but all that while responding to ever-increasing customer expectations. Within this challenge, predictive analytics is rapidly becoming a solution. It allows companies to make better decisions and be more efficient throughout the entire logistics planning process. At the core of this transformation is logistics software.

By combining predictive analytics with an AI-enabled logistics software platform, organizations can move away from a reactive approach to a proactive approach in decision-making. Let’s take a look at how predictive analytics is changing logistics. Plus why investing in the right logistics management system (LMS) is essential to doing business.

The Rising Complexity of Logistics Planning

Supply chains have become more connected and more fragile than ever. A single delay at a single port can cascade all the way across the globe. This can result in a deadline that is missed and a very unhappy customer. According to McKinsey, companies will experience supply chain disruptions lasting a month or more once every 3.7 years. As a result, companies cannot afford to plan using old-fashioned-up-on-the-l19)store-and-go-in-a-store techniques anymore.

This is where logistics planning software comes to the rescue. Importantly, modern logistics planning software featuring predictive analytics uses real-time data to pinpoint bottlenecks. Modern logistics planning software offers advantages over old forecasting and spreadsheets. This allows planners to identify better improvement opportunities, even before the planning process can focus on the actual improvements.

For example:

– Retailers can more precisely predict seasonal shifts in demand.

– 3PLs can also foresee a delay in a route due to traffic or weather.

– Manufacturers can predict a lack of inventory in their raw material supply chain and adjust sourcing.

Predictive analytics is like a crystal ball, but rather than using intuition and magic, it uses data.

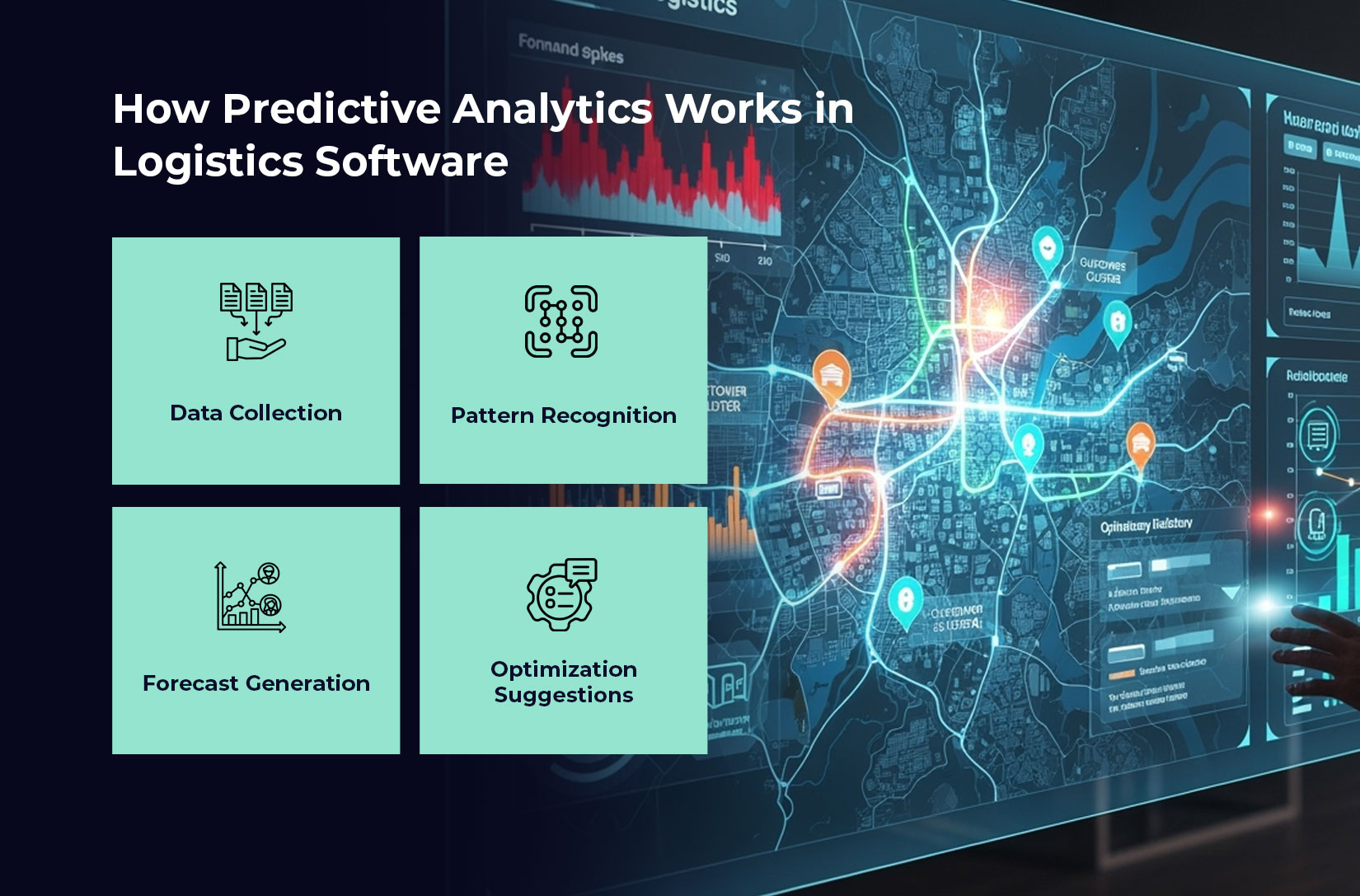

How Predictive Analytics Works in Logistics Software

In logistics, predictive analytics is driven by complex algorithms, artificial intelligence, and machine learning. These components analyze enormous amounts of historical and real-time data to provide actionable predictions. Here’s how it works in a logistics management software context:

1. Data Collection:

IoT sensors, GPS trackers, ERP systems, and customer order entry provide continuous data into the logistics management software.

2. Pattern Recognition:

AI-driven logistics software identifies common patterns, whether it be recurring traffic congestion, seasonal surges, or delayed supplier shipments.

3. Forecast Generation:

The LMS makes predictions about possible disruptions, inventory shortages, or delivery delays.

4. Optimization Suggestions:

The LMS provides alternative routing, revises capacity planning, or activates automated messaging to stakeholders.

By incorporating predictive analytics, logistics management software transitions from a preservation system to a decision-making system.

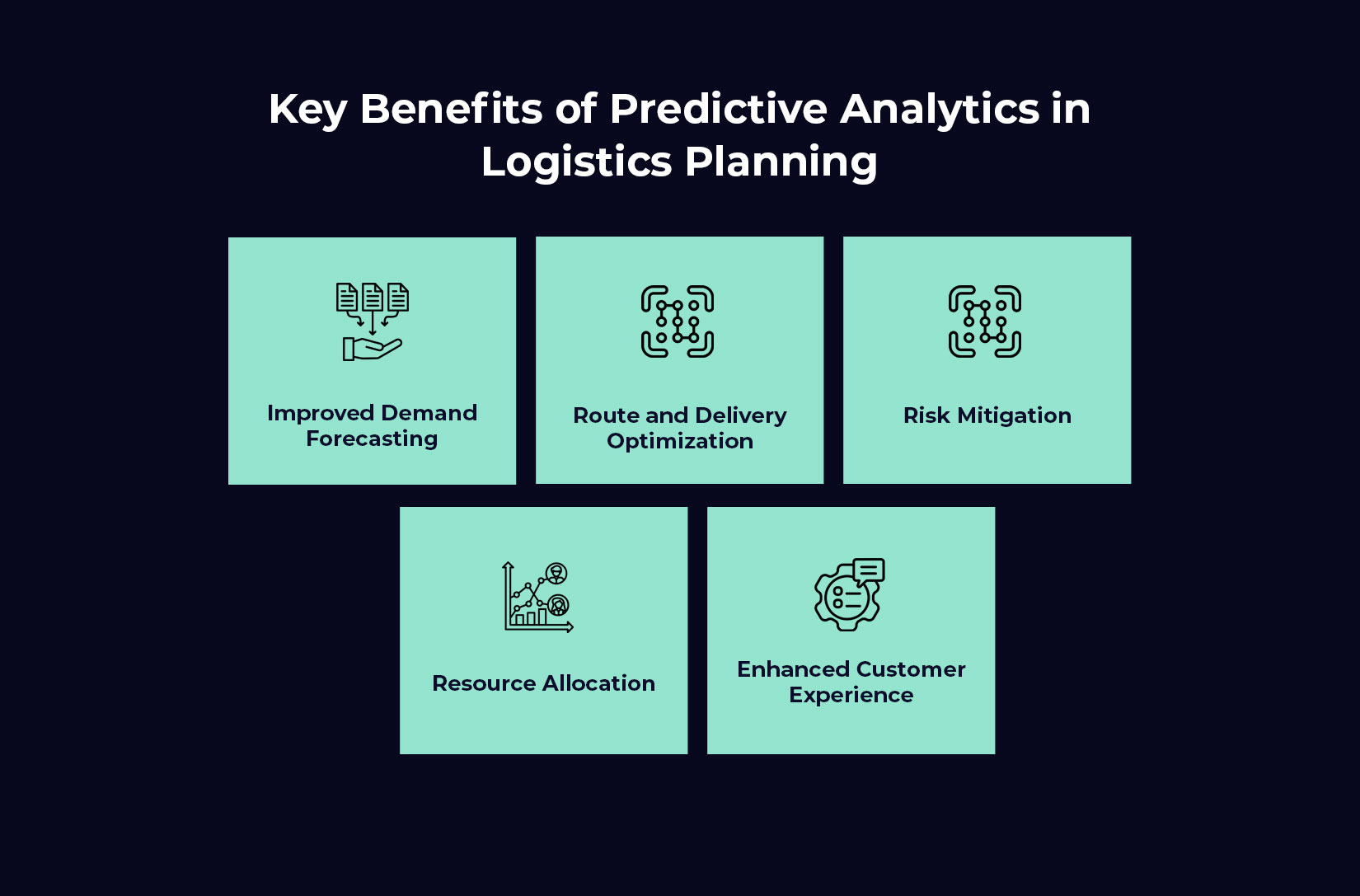

Key Benefits of Predictive Analytics in Logistics Planning

1. Improved Demand Forecasting:

Companies can reduce inventory costs by up to 10–20% based on solid demand forecasting (Deloitte). Predictive consumer insights empower logistics planning software to align supply with demand while reducing waste.

2. Route and Delivery Optimization:

Predictive analytics considers factors such as traffic speeds, fuel costs, and delivery windows. As a result, logistics players can reduce transportation costs by as much as 15%. As an added benefit, this improves on-time delivery rates, central to success for any delivery service, but especially e-commerce and pharmaceuticals.

3. Risk Mitigation:

A good logistics management system tracks risks and predicts them. For example, using weather data, fleet managers can see if wind speeds or rain will impact delivery schedules, and make alternative arrangements if necessary.

4. Resource Allocation:

Whether it is managing labor schedules or optimizing a warehouse space, predictive models allow for optimum resource allocation. Running out of space in a warehouse or having access to too much labor can be costly swings.

5. Enhanced Customer Experience:

Customers expect certainty. They expect transparency and reliability. AI driven logistics software can track packages and provide accurate ETAs for deliveries. Being able to have this type of visibility into a transaction needs to foster trust and enhance retention.

Why Predictive Analytics is a Must-Have for LMS

A modern logistics management system (LMS) without predictive tools is like driving with a blindfold. The logistics industry is moving at an amazing pace, and the companies that do not utilize predictive technologies will get left behind. Here is why predictive analytics are now a ‘must-have’:

– Global supply chain volatility is increasing.

– Customer expectations for fast and accurate deliveries have never been higher.

– Competition is investing in AI-based logistics software.

Gartner predicts that by 2027, more than 50% of supply chain organizations will use artificial intelligence and advanced analytics for planning.

Challenges in Implementing Predictive Analytics

While the advantages are apparent, companies encounter several barriers to implementing predictive analytics in their logistics planning software.

1. Data Quality Issues:

Predictive models are only as good as the underlying data. When the quality of data is incomplete or inaccurate, dependability is reduced.

2. Integration Complexity:

Integrating predictive analytics into existing logistics management systems is a technical challenge, which can take a lot of time and patience.

3. Change Management:

Teams need to learn to use a new tool and trust insights from a machine and algorithms. Instead of relying on experience or mix human intuition and artificial intelligence.

4. Cost Concerns:

Implementing advanced logistics management solutions means significant upfront costs, which can be overwhelming for smaller businesses.

Even with these barriers, the long-term ROI ismuch greater than the initial barriers to overcoming.

The Future of Logistics Planning with Predictive Analytics

Predictive analytics is just the tip of the iceberg. With the expansion of data sources and improvement of algorithms, logistics software will increasingly offer even more sophisticated features:

– Prescriptive Analytics: Going beyond predictions and recommending the best options for the future.

– Autonomous Decision-Making: LMS platforms that reroute shipments without human intervention.

– Sustainability Insights: Predictive tools to help companies minimize carbon emissions and satisfy ESG goals.

The future is able to get to an ecosystem where predictive analytics, artificial intelligence and automation come together to provide truly intelligent logistics planning software.

Conclusion

Predictive analytics is revolutionizing logistics —moving from a reactive function, to a proactive, datacentric decision machine. When predictive capabilities are integrated within logistics software, organizations can prepare for demand, optimize routes, mitigate costs, and improve consumer experiences.

An effective logistics management system (or logistics management solution) enabled by AI is no longer a luxury—it is a competitive advantage. Organizations embracing predictive analytics today will not only endure a disruption in the supply chain, they will prosper in it.

Whatever you take away from this article, just know: predictive analytics is not just bolstering logistics planning, but transforming logistics planning. So, to plan in the best way, you need the help of the best logistics software in the market by LogiNext Solutions. Click on the red button below and book a demo today!

36

@LogiNext