From Breakdowns to Breakthroughs: AI Maintenance for Fleets

Fleet operations are evolving at a rapid rate. Something that required manual monitoring and guesswork is now operated by real-time data and intelligent automation. With tools being powered by AI are transforming transportation, predictive maintenance is not a luxury anymore but a necessity. Businesses are now turning to fleet management software to cut costs, improve uptime and plan maintenance more strategically.

The High Cost of Reactive Maintenance

Fleet downtime costs businesses billions each year. As per a report by American Trucking Associations, the avg. cost of a random truck breakdown can range between 400-760$. The cost can be a reason of lost productivity, repairing or missed deliveries. Adding the risk of safety violations or penalties due to poor health, and the effect becomes two-three fold.

Traditional methods of maintenance, where the vehicles are fixed only after a problem arises are reactive by nature. This approach leads to higher costs, but at the same time also increases the chances of unexpected failures. This is where AI comes into play.

Enter Predictive Maintenance with AI

Artificial Intelligence has opened new ways in how fleets are managed. AI algorithms can detect patterns and anomalies before a breakdown even occurs. AI does this by using the data collected from onboard sensors, telematics devices and maintenance logs. This results in a fruitful thing for the fleet managers. They can now anticipate issues, schedule repairs proactively and extend vehicle lifespans.

This particular shift is central to today’s fleet management software powered by AI. It is transforming preventive maintenance to predictive maintenance.

How Does AI Predict Maintenance Needs?

Modern fleet management system uses AI and Machine Learning (ML) to analyze:

– Engine diagnostics: Monitoring of temperature, fuel consumption and RPM fluctuations.

– Tire pressure and break health: Detecting wear and tear patterns.

– Driving Behavior: Estimating the stress on vehicle parts by analyzing idle time, harsh breaking and acceleration.

– Historical Maintenance Data: Predicting the future issues by learning from the mistakes of the past.

By incorporating the above insights, the system creates a maintenance schedule tailored to each vehicle. This helps in minimizing guesswork and maximizing operational efficiency.

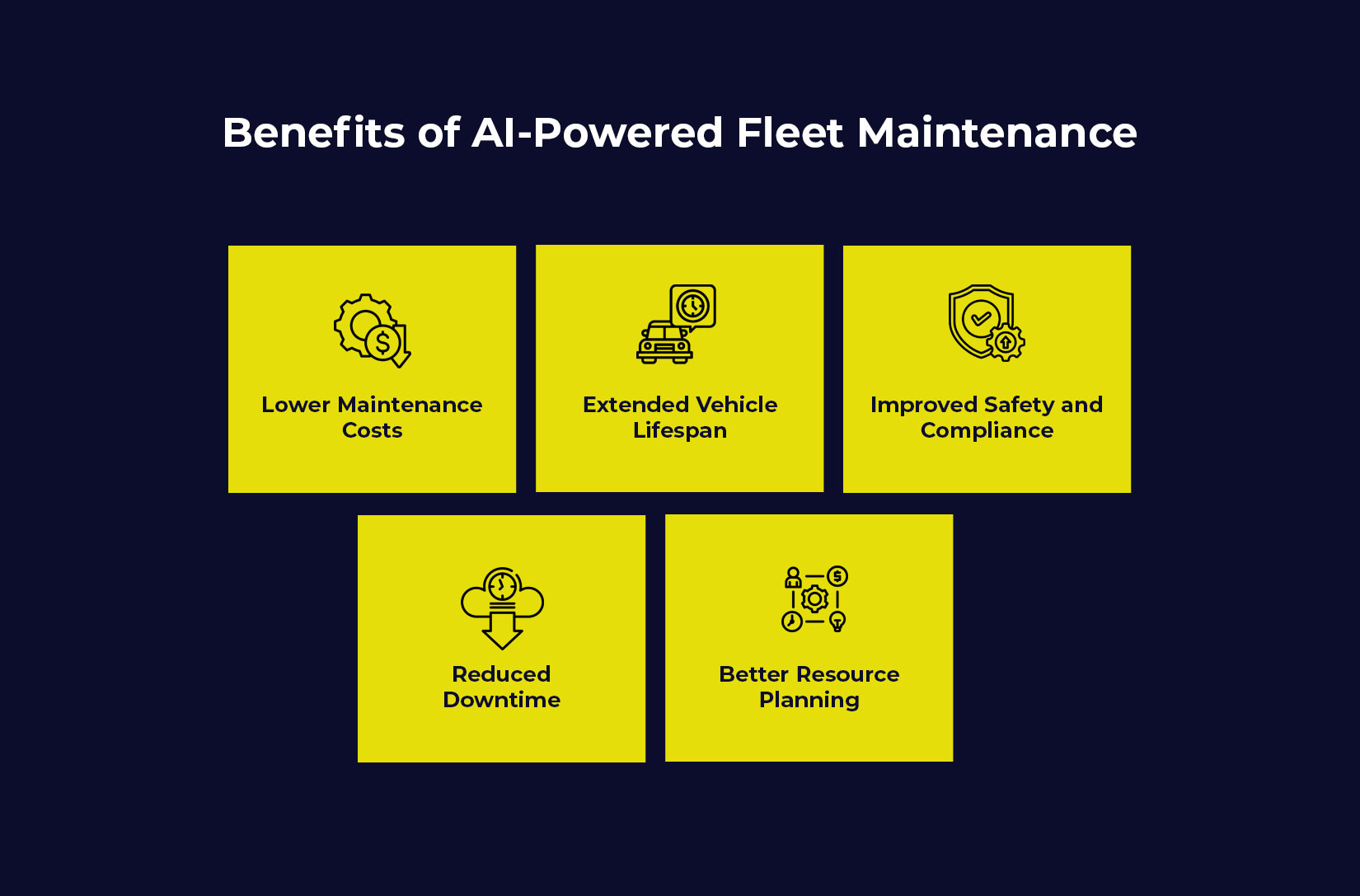

Benefits of AI Powered Fleet Maintenance

Adopting an AI powered fleet management software goes beyond just avoiding breakdowns. Here’s how the businesses benefits:

1. Lower Maintenance Costs:

AI enables services which are just-in-time. Fleet managers maintain and service vehicles based on actual conditions rather than following rigid service intervals. This helps in reducing unessential maintenance and avoid major repairs. As per McKinsey, companies using AI-based maintenance have reported up to 30% reduction in repair costs.

2. Extended Vehicle Span:

The system can prevent minor issues from escalating. This can be done by using predictive diagnosis to reduce wear and tear. Thereby, vehicles can stay roadworthy for longer periods, deferring replacement costs.

3. Improved Safety and Compliance:

Businesses can enable that their fleets meet regulatory standards and reduce accident risks. This can be done by proactively fixing critical components. For regulated industries like freight and food delivery it is very crucial.

4. Reduced Downtime:

By inducing automated alerts and proactive scheduling, businesses can keep vehicles on the road. A report by FreightWaves (2023), some logistics firms have cut fleet downtime by up to 40% using AI tools.

5. Better Resource Planning:

Businesses by knowing in advance which vehicles will be in the shop and when, can schedule routes and drivers more efficiently. This will directly support better service-level-agreements (SLAs) and improved customer satisfaction.

The Role of Fleet Management Software in AI-Driven Maintenance

AI needs data to deliver insights. This is why a robust fleet management software is the cornerstone of predictive maintenance. These platforms integrate GPS, diagnostics and IoT, because of this it can create a centralized dashboard that offers complete visibility into fleet health.

The best fleet management software provides:

1. Centralized Data Hub:

The system gathers data from GPS, onboard diagnostics and IoT sensors into one single unified platform. This will provide real-time visibility into location of the vehicle, performance and health metrics.

2. Predictive Alerts:

The system can detect irregularities before they become failure. This is done with the help of AI algorithms- it analyzes real-time and historical data. The system then sends automated alerts, allowing teams to act before breakdowns occur.

3. Smart Workflows:

The software when the issues are identified, can automatically generate work orders and assign tasks. This ensures a faster, more efficient maintenance process by removing manual steps.

4. Custom Rules:

Fleet managers can set service rules based on mileage, operating hours or usage trends. This helps the fleet managers by ensuring alerts and schedules are tailored to specific fleet requirements.

5. Insightful Dashboards:

Dashboards help in visualizing trends- engine health, fuel efficiency and service history. These insights are beneficial for managers. As these insights can help in making proactive decisions and optimize long-term fleet performance.

6. System Integrations:

Fleet management software is easily able to connect with external platforms such as fuel card systems, ERPs and repair shops. This creates a seamless ecosystem that streamlines fleet operations end-to-end.

7. Remote Accessibility:

Through remote access managers can monitor fleet health, view alerts and approve tasks from anywhere at anytime. Managers respond faster and avoid delays by instantly accessing updates

AI takes these capabilities and turns them into action. If the system detects an increase in engine temperature and a decrease in fuel economy, it can trigger a work order or alert maintenance to the issue, before an engine failure.

AI + Fleet Management System = Scalability

With fleet size increasing, managing these fleets manually can become untenable as a massive fleet management system that uses AI can manage hundreds or thousands of vehicles without losing accuracy. This makes it an optimal solution for logistics providers, courier service providers, construction companies, and last-mile delivery networks.

Moreover, companies using AI managed fleet management solutions have seen their operational resilience significantly improved. This is especially during peak delivery times.

AI Maintenance in Action: Real-World Impact

Case Study: National Logistics Co. (NLC)

NLC operates a delivery fleet made up of 500 vehicles in 20 cities. Before NLC implemented AI, the fleet experienced an average of 18 unplanned breakdowns per month, disrupting its strong customer service ethos. Following the AI backed fleet management system, breakdowns in vehicles after an initial 6 months were reduced by 65 percent.

The AI based fleet management software predicted when real-time sensor data would need maintenance. High-risk vehicles were serviced earlier while low-risk vehicles remained on the road longer. Therefore, the company not only saved over $200,000 annually in maintenance costs, they also enhanced their on-time delivery performance by 12 percent.

Conclusion

Get rid of the old story of reactive fleet maintenance. With fleet management software powered by AI, businesses transition from reactive fire-fighting responses to intelligent planning. They experience reduced breakup, better uptime, safer vehicles, and healthier margins.

Investing in the best fleet management software is no longer about tracking vehicles. It is about keeping them in optimal working order with intelligence that never sleeps. The future of fleet management will be predictive and that future is now. So, don’t wait up and click on the red button below today. Book a demo with LogiNext Solutions and get the best fleet management software.

49

@LogiNext