Why Legacy TMS Is Holding Your 3PL Back and How LogiNext Fills the Execution Gap

The 3PL industry is rapidly growing-but many providers are running on technology designed for a much slower era. Today, third-party logistics providers operate in a world of same-day deliveries, tight SLAs, fluctuating demand, and customers who expect Amazon-level visibility. Yet a large number of operators still rely on legacy TMS platforms. These focus more on planning freight than executing it reliably.

This misalignment is expensive. In fact, more than 60% of logistics providers report that limitations in technology prevent them from scaling profitably. The result is an expanding execution gap-one that traditional transportation management systems were never designed to manage.

The Execution Reality of Modern 3PL Operations

Third-party logistics is no longer merely about taking freight from A to B. A modern 3PL manages multi-carrier networks, dynamic delivery promises, reverse logistics, hyperlocal distribution, and real-time customer communication. In a nutshell, execution is no longer optional-it is the business.

However, most legacy TMS software for 3PL was designed with a different objective in mind: rate management, load tendering, and basic routing. These systems work fine in static environments. They fail in highly dynamic, last-mile-heavy operations where conditions change by the minute.

For organizations dealing with eCommerce, retail, or on-demand fulfillment, this produces daily friction.

Where Legacy TMS Falls Short for Logistics Providers

Let’s be direct: Legacy TMS platforms were never designed to handle the third-party logistics complexity of today. This is where they break down:

1. Planning-Centric, Execution-Poor:

Traditional 3PL logistics software is heavily focused on upfront route planning. Once the vehicle is on the road, execution is an afterthought. There is limited real-time visibility, weak exception handling, and little automation.

This lack of operational intelligence results in missed SLAs and manual firefighting in an execution-heavy environment where disruptions are routine.

2. Limited Last-Mile Capabilities:

Legacy platforms struggle with:

– Multi-stop optimization.

– Constraints related to hyperlocal delivery.

– Failed delivery handling.

– Dynamic rerouting.

Yet last-mile execution accounts for more than 40% of total logistics costs. If your logistics software for 3PL cannot manage last-mile complexity, the margins erode in no time.

3. Manual Workflows at Scale:

Legacy third-party logistics software forces teams to resort to using spreadsheets, calls, and manual updates to manage the ever-growing order volumes. The dispatchers become bottlenecks: ops teams spend more time managing systems than managing outcomes.

This is one of the reasons many logistics firms are reporting 20–30% operational inefficiency despite heavy investments in TMS platforms.

4. Poor Customer Visibility:

End customers want live ETAs, proactive alerts, and proof of delivery. This is rarely natively supported by legacy TMS solutions. For 3PLs, this leads to more “Where is my order?” tickets and lower customer satisfaction scores.

In 3rd party logistics, visibility is no longer differentiating-it is table stakes.

The Hidden Cost: Lost Growth for Providers

These limitations do more than slow operations, they directly restrict growth. Many 3PLs turn down new contracts because their systems cannot:

– Support multiple service levels.

– Integrate with client systems quickly.

– Scale execution without headcount additions.

In fact, surveys conducted show that approximately 50% of providers lose deals due to technology gaps, not pricing. Legacy TMS becomes a silent growth killer.

Why Execution-First Technology Matters

A Modem 3PL Logistics System Requires the use of new software that will enhance the capabilities of the existing TMS Measurement System.

Next Gen Technology of 3PL will include but are not limited to the following:

– Automated Dispatch with real-time visibility to dispatch & route.

– Real-time visibility to the execution of both customer and carrier communication.

– AI-driven exception resolution capabilities.

– Continuous ETA recalculation.

– Customer and carrier communication in real time.

This is not about replacing planning. This is about operationalizing it at scale.

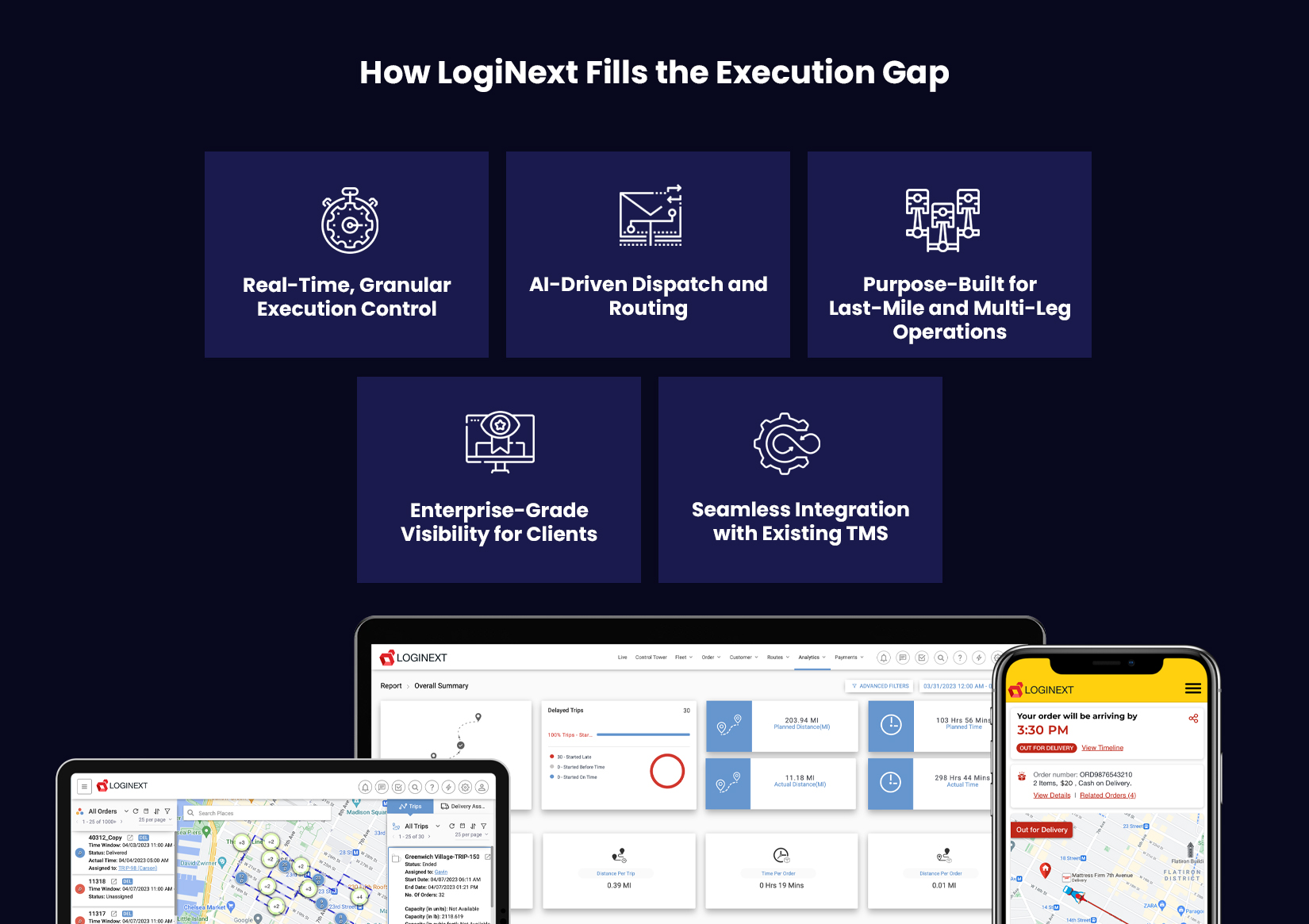

How LogiNext Fills the Execution Gap

LogiNext has been custom-built to cater to the gaps in execution that are left behind by legacy TMS software for 3PLs. It forms an operational layer turning plans into consistent results.

1. Real-Time, Granular Execution Control:

LogiNext empowers logistics operators to track every delivery, vehicle, and exception in real time. There is no static route plan but dynamic execution intelligence that adjusts for delays, traffic, and changing customer availability.

This is especially critical for high-volume 3PL environments that are managing thousands of daily stops.

2. AI-Driven Dispatch and Routing:

Unlike rigid TMS logic, LogiNext uses AI to constantly optimize routes and assignments. It automates dispatch decisions and weighs those decisions against SLAs, capacity, and cost.

For 3rd party logistics providers, this means:

– Higher vehicle utilization.

– Fewer failed deliveries.

– Lower cost per stop.

3. Purpose-Built for Last-Mile and Multi-Leg Operations:

With LogiNext, complex execution models are supported, from first mile to last mile, including reverse logistics. Thus, making this a very powerful logistics software for 3PL handling omnichannel and eCommerce-heavy clients.

It fills the functionality gaps that traditional third-party logistics software leaves unresolved.

4. Enterprise-Grade Visibility for Clients:

LogiNext offers branded tracking, proactive notifications, and real-time ETAs. This directly improves end-customer experience and reduces the support workload.

For 3PLs, the concept of visibility is revenue enabling-not a cost center.

5. Seamless Integration with Existing TMS:

Importantly, LogiNext does not require ripping out existing systems. It integrates with legacy TMS software for 3PL, upgrading execution without interfering with key planning workflows.

This makes the adoption faster and ROI tangible in months, not years.

The Competitive Advantage for Modern Logistics Providers

The Third-Party Logistics Market is going to cross $1.5 trillion by 2027. Such growth will not favor the biggest players but the most operationally agile among them.

Those organizations that are still relying on pure legacy systems will struggle to:

– Protect margins.

– Meet tightening SLAs.

– Scale execution efficiently.

Those that adopt execution-first platforms, such as LogiNext, position themselves as technology-enabled partners-not just capacity providers

Final Thoughts

Legacy TMS platforms are not broken, just incomplete. For today’s 3PL, they solve only half the problem. The real challenge falls to execution, where delays, costs, and customer perception are decided.

LogiNext bridges this gap by complementing traditional third-party logistics software with real-time, intelligent execution capabilities. For 3PLs focused on growth, profitability, and differentiation, closing the execution gap is no longer optional-it is mission-critical.

In a market where service is the product, execution means everything. And legacy TMS alone no longer gets the job done. So, its healthy to take a switch from legacy systems and bet on the best software provided by LogiNext. Click on the red button to know more.

44

@LogiNext