Why Disconnected Data Blocks Modern Supply Chain Management

In theory, data must be the fuel of any modern supply chain management. However, in reality a lot of supply chains still run on spreadsheets, emails and isolated platforms. This is a mess of disconnected systems which are spanning geographies, partners and operations.

When data is fragmented, it cripples visibility. The transportation, logistics teams are spread around the globe, working individually, this leads to decisions are taken or partial or outdated information. This becomes a very dangerous games when delays, demand fluctuations or disruptions are the new normal.

To put this bluntly, disconnected data turns any supply chain into a slow-moving beast. Rather than anticipating issues and adjusting in real time, companies are stuck in the traditional methods. The more technology evolves, the wider the gap becomes for those who ignore it.

What Happens When Data Doesn’t Talk

1. Operational Inefficiency and Wasted Time:

When data is sorted through spreadsheets, emails or legacy systems, the staff end up performing the repetitive manual data entry. Every duplicated invoice, inventory record, or shipment update eats into valuable time, time that should go toward planning, not paperwork.

2. Poor Visibility, Erratic Inventory and Risk of Stockouts or Overstocks:

Disconnected data conceals real-time status of inventory and logistics. Without a connected and unified view, teams may not know what is actually in stock. Logistics team cannot always predict delays and there might be over ordering or under ordering of things. This results in mismatch between supply and demand.

3. Slow Response in Disruption and Mounting Costs:

Disruptions-a congestion of ports, labor issues, and customs delays-are inevitable. But when systems are fragmented, the lag between what happens and what teams see can cost heavily. Delays, demurrage fees, lost sales, and unhappy customers-these all stem from an inability to respond fast.

4. Lack of Strategic, Data Driven Decision Making:

When data needs to be reconciled, cleaned, and continually verified, teams spend more time correcting records than they do analyzing them. That kills agility. In a world where the management of supply chains increasingly depends on speed and precision, that’s a strategic disadvantage.

5. AI Ambition Dead on Arrival:

AI – predictive analytics, smart routing, anomaly detection does not work on individual, inconsistent data sets. For an AI-driven supply chain management software to delivery, you need clean and unified data. Without that data, these advanced tools are little more than decoration.

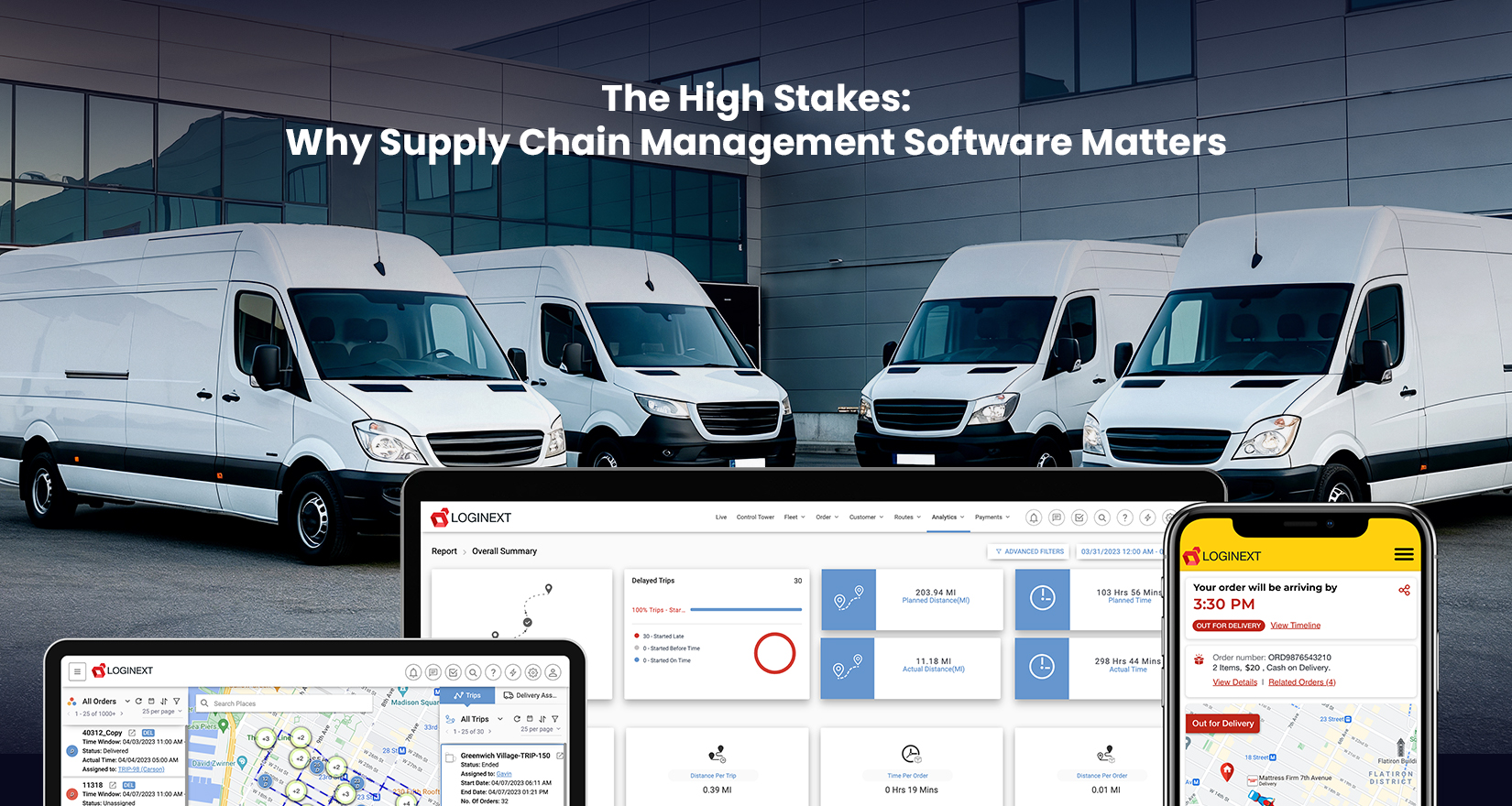

The High Stakes: Why Supply Chain Management Software Matters

This is where a modern supply chain management solution comes in. A platform which is designed to unify data across procurement, warehousing, transportation and operations. By integrating fragmented data sources into a central system, companies are able to gain a single version of truth.

With a powerful supply chain management system, teams are enabled to:

– Access real-time dashboards showing inventory, shipment status, ETAs across partners.

– Automating manual tasks – data entry, reconciliation, reporting.

– Easy to share the information with suppliers, carriers, warehouses and stakeholders.

– The ability to make better choices faster. Carrier, route, supplier, buffer stock and others based on facts not guesswork.

One study reported that 20% of the responding organizations cited disconnected core systems as a root cause for slow reaction times in the face of disruption.

And the scale of the data challenge isn’t trivial: global data creation is exploding. As companies generate torrents of supply chain data, the growth of data silos outpaces any human’s ability to keep up.

In other words-you need supply chain management software. Without it, you’re trying to sail through a storm in a leaky boat.

Building the Foundation for AI-Driven Supply Chain Management

The beauty and advantage of investing in a unified system is that you are not only fixing today’s inefficiencies but also preparing for tomorrow’s possibilities. A clean, structured data helps in laying groundwork for AI-driven supply chain management.

Once data is integrated:

– Predictive analytics, with anomaly detection works well. With this you can anticipate delays, forecast demand and avoid stockouts.

– By comparing the ETAs vs actuals, companies can benchmark the performance. With this it can spot bottlenecks and choose optimal routes or suppliers.

– In the longer term, AI tools acting on behalf of the managers, can automate logistics decisions. Decisions like confirming shipments, selecting carriers, rerouting in real-time.

But this isn’t magic. It takes implementation discipline to do so. You really need to map where your data lives today, standardize it, and then integrate across the ecosystem. Identify spreadsheets, ERP, email, and partner systems where information resides. Then pick a supply chain management solution that supports integration needs-to-core systems for real-time dashboards, document sharing, automation features, and scalability.

Why the Risk of Staying Disconnected Is Too High to Ignore

In today’s economy, volatility is the norm. Disruptions from labor issues, geopolitical risk, weather, and demand surges-they come fast and furious. A fragmented supply chain isn’t just inefficient; it’s fragile.

When data is disconnected:

– Lead times become unpredictable.

– Costs spiral upwards-from emergency freight to inventory holding to labor waste.

– Delays, stockouts, or miscommunication hurt customer satisfaction.

– Growth through strategies becomes almost impossible.

Meanwhile, companies that take an integrated, data-driven approach-with the use of appropriate supply chain management software-gain agility, reduce risk, improve margins, and build resilience.

Conclusion

Take a step back and evaluate how you are managing supply chain operations today. With the use of spreadsheets, e-mail chains, and piecemeal systems, you are likely to have difficulty identifying where your logistics, inventory, procurement, shipment, and partner data exist.

Is there a comprehensive view of the supply chain or do you only have piecemeal views of information? Investing in a comprehensive supply chain management system is no longer a choice; it is a strategic decision. This decision makes the difference between being reactionary versus being proactive and between merely putting out fires and developing a strategic plan.

If you want your supply chain to be successful (and grow) in an AI-Enhanced Manufacturing industry, having a unified data structure will be essential. If you cannot connect your data, you cannot fully maximize the use of AI. And you are already behind without the maximum benefit from AI. So don’t wait, click on the red button and book a demo with LogiNext today.

27

@LogiNext