Logistics in 2026: Technology Trials to Execution

Logistics management is at an inflection point in 2026, where vision turns into measurable value. After years of pilots, proofs of concept, and reactive tech spending, companies are now fully shifting focus to execution. The priorities driving this change aren’t just about flashy tech for its own sake; they are about hard metrics such as operational efficiency, sustainability outcomes, customer expectations, and labour realities.

In this landscape, investment in logistics management software and logistics software that delivers predictable performance is no longer optional. Tools that support integration, automation, and intelligence are the engines powering supply chains into the future and AI sits squarely at the wheel.

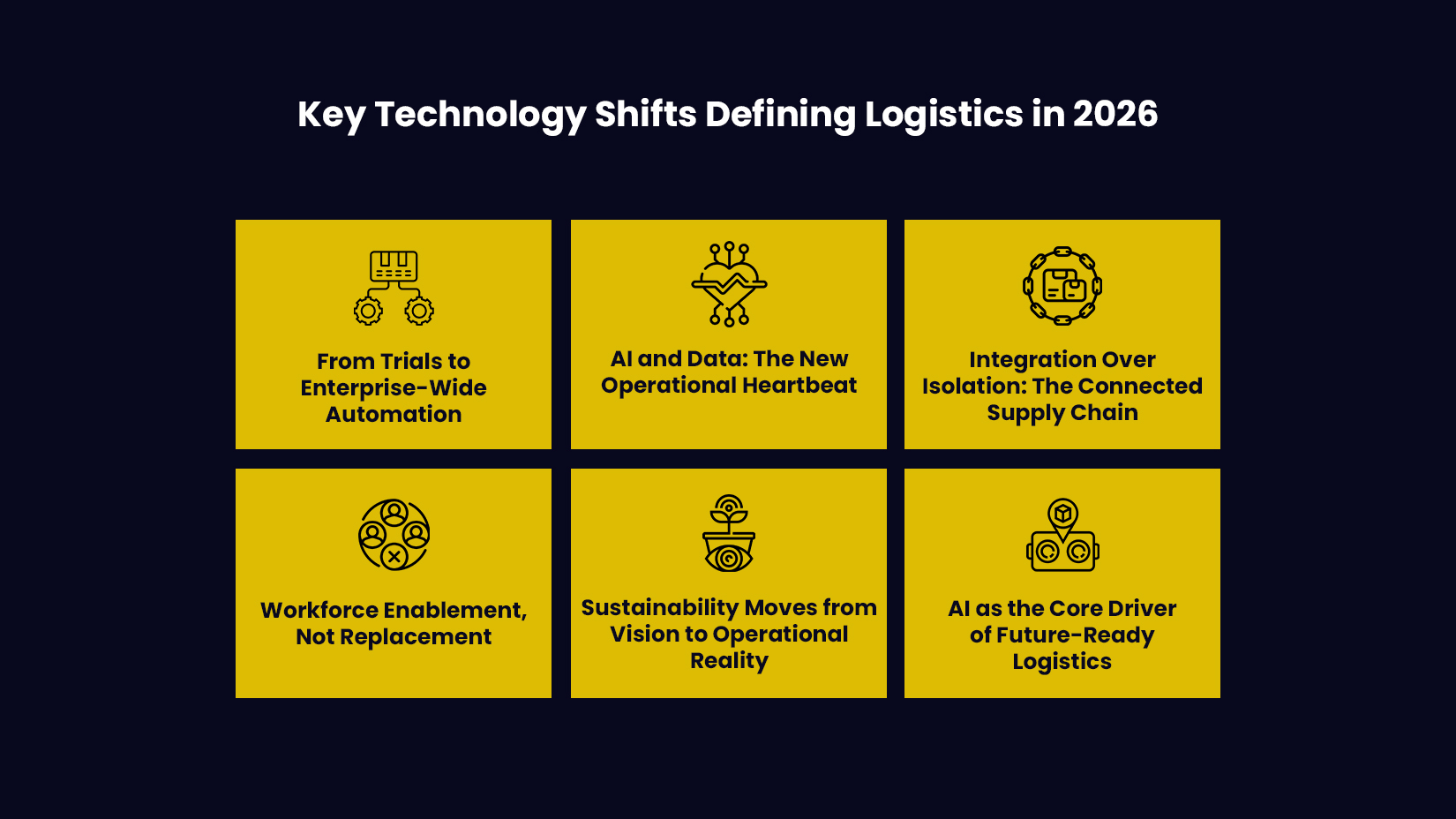

Key Technology Shifts Defining Logistics in 2026

1. From Trials to Enterprise-Wide Automation:

One of the defining narratives of 2026 is the end of isolated pilots and the rise of connected automation. Automated warehouses and distribution centres no longer test robots or conveyors on a limited scale. Instead, they deploy fully integrated systems that cover entire facilities, connecting robotics, conveyors, and execution platforms into unified architectures.

This shift transforms logistics management software from departmental tools into enterprise-critical infrastructure. Vendors that once licensed WMS modules now support broad automation stacks capable of real-time orchestration. Efficiency gains once “theoretically promising” in trials are now delivering measurable throughput, accuracy, and labour productivity improvements.

2. AI and Data: The New Operational Heartbeat:

Traditional logistics systems were reactive. In 2026, leaders are fully dependent on AI powered logistics software and AI powered logistics solution platforms to convert data into real-time, predictive decisions.

AI now:

– Predicts bottlenecks before they even escalate.

– Optimises resource allocation continuously.

– Adjusts workflows based on live conditions.

– Enhances visibility for both logistics and business teams.

This is where logistics management powered by AI truly transforms operations pushing organisations from analysis toward automated execution. Companies still relying on legacy systems face slower response times, blind spots, and higher operational risk.

3. Integration Over Isolation: The Connected Supply Chain:

In 2026, disconnected tech stacks are operational liabilities. Businesses increasingly adopt integrated logistics software platforms that unify transportation, warehousing, inventory, and customer fulfilment systems.

This level of connectedness moves logistics management beyond planning and into dynamic, real-time control. Leaders can now address disruptions, supply delays, capacity shortages, demand spikes the moment they occur, not hours later. Legacy systems generating after-the-fact reports are being phased out rapidly.

4. Workforce Enablement, Not Replacement:

Automation and AI aren’t erasing jobs; they’re reshaping them. Companies now design human-machine workflows to solve labour shortages, eliminate repetitive tasks, and improve workplace safety.

Machines handle:

– Repetitive picking.

– High-risk lifting.

– Continuous scanning.

Humans focus on:

– Exception management.

– Customer communication.

– Strategic planning.

The result is a more resilient workforce strategy grounded in technology-driven efficiency.

5. Sustainability Moves from Vision to Operational Reality:

Sustainability is now woven into everyday logistics management. Businesses are:

– Deploying EVs for urban logistics.

– Reducing warehouse energy consumption.

– Using advanced routing to cut idle time and fuel waste.

AI powered logistics solution platforms help balance cost, speed, and environmental impact, making sustainability both measurable and manageable. With tightening regulations and rising customer expectations, sustainable logistics is no longer a marketing line; it’s a competitive advantage.

6. AI as the Core Driver of Future-Ready Logistics:

AI is no longer a buzzword. Its role has expanded into orchestration, prediction, and continuous optimization across the supply chain. Companies using logistics management powered by AI report double-digit improvements in fulfilment accuracy, labour productivity, and asset utilisation.

Some commonly reported industry outcomes include:

– 10–30% improvement in planning accuracy.

– 20–40% reduction in operational downtime.

– 15–25% boost in delivery performance.

In an environment where every minute and dollar counts, AI is becoming the primary differentiator between logistics leaders and laggards.

The Bigger Picture: The Future Is Execution-Focused

The overarching story of logistics in 2026 is a shift from curiosity to accountability. Technologies that once lived in experimental sandboxes from robotic fleets to AI forecasting, are now essential operational tools. Here’s what that means:

– Software adoption is strategic: Companies choose platforms that can grow with them rather than short-term hacks.

– AI is embedded everywhere: Decision support, execution logic, and proactive insights are no longer optional.

– Integrated logistics stacks outperform isolated tools: Seamless data flow beats siloed applications.

– Human + machine workflows deliver real value: Automation supports workforce empowerment and safety.

– Sustainability is a competitive differentiator: Operational systems are now judged on environmental outcomes as much as efficiency.

This evolution underscores a simple truth. Logistics excellence in 2026 isn’t about having technology, it’s about deploying the right technology in ways that scale, integrate, and deliver measurable outcomes. Firms that succeed will be those that treat logistics management software and AI powered logistics software as strategic investments, not experimental toy boxes.

Conclusion

In a world where speed, reliability, and sustainability define competitiveness, logistics teams must think differently. It’s no longer enough to trial cool tools, organisations must embed powerful logistics software, AI, and integrated systems into their operational DNA.

The compass for logistics in 2026 points toward execution, not exploration. As businesses stretch to meet customer expectations and market volatility, the adoption of advanced, AI-enabled logistics platforms will continue to separate leaders from laggards. Those that harness logistics management powered by AI will move goods smarter, faster, and more sustainably and they’ll thrive in a marketplace that rewards real results, not just buzzwords. Click on the red button below and book a demo with LogiNext today.

18

@LogiNext