3 Supply Chain Trends for 2026: What Every Leader Must Know

In 2026, supply chain management is no longer just an operational duty, it’s a strategic differentiator. Global disruptions, rising customer expectations, and rapid tech adoption are reshaping how products flow from raw material to doorsteps. To compete, organizations must understand the emerging trends driving the future of efficient, resilient, and profitable supply chains.

This blog explores the top three trends shaping supply chain management in 2026. It explains why they matter, and highlights how modern systems and platforms are empowering businesses to lead, not just react.

Trend 1: Hyper-Connected Supply Chain Ecosystems

From Linear to Networked

Traditional supply chains followed a linear path. That’s no longer enough. Today’s supply chains resemble complex ecosystems with suppliers, logistics partners, manufacturers, and customers all interacting in real time. This shift demands a strong supply chain management platform that supports seamless communication across partners.

Why It Matters

- 24/7 operations: Customers now expect instant updates and faster delivery.

- Dynamic disruptions: Weather events, geopolitical shifts, and labor shortages can hit without warning.

- Complex sourcing: Multiple suppliers across continents increase risk without real-time oversight.

In this environment, tools like supply chain management software and supply chain visibility software are essential. They help teams monitor thousands of moving parts and make decisions quickly.

Growth Is Evident

Analysts estimate that by 2026, organizations investing in integrated supply chain management systems will reduce operational costs by up to 20% and improve on-time delivery rates by over 15%. These gains stem from better coordination between planning, execution, and monitoring functions.

What Leaders Should Do Now

- Invest in unified platforms: Choose a supply chain management platform that breaks data silos. One platform should handle procurement, logistics, planning, and customer service.

- Integrate partners: Encourage suppliers and carriers to share data through APIs and collaborative dashboards.

- Monitor performance in real time: Enable alerts and automated responses for exceptions.

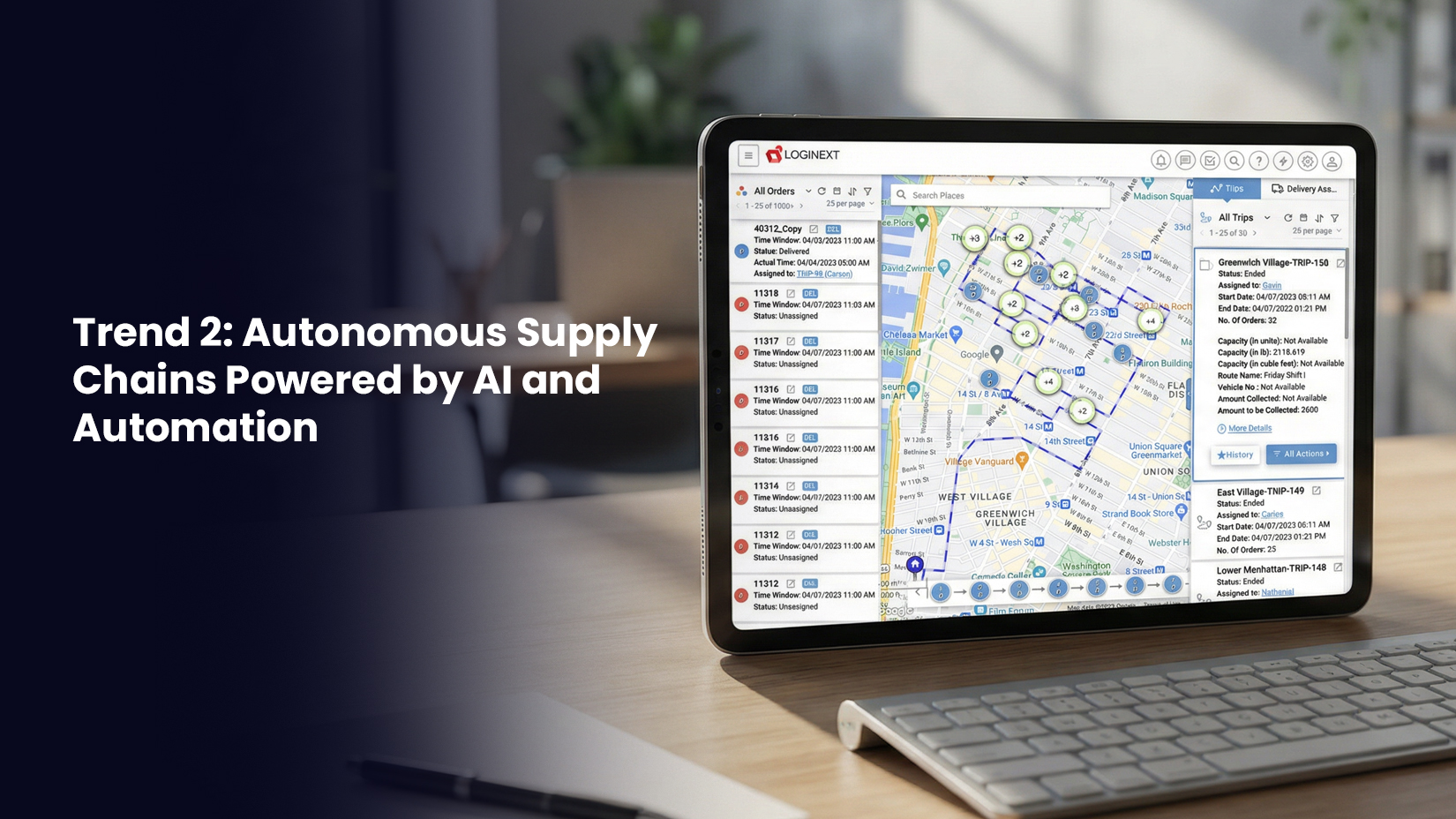

Trend 2: Autonomous Supply Chains Powered by AI and Automation

The Rise of Self-Driving Operations

In 2026, supply chains aren’t just smart, they’re starting to act autonomously. This means automated planning, AI-driven execution, and systems that self-correct before issues escalate. Leaders are moving beyond basic reporting in their supply chain management platform to true automation that runs planning, procurement, and execution with minimal human intervention.

What Autonomous Supply Chains Look Like

- Automated demand forecasting: AI predicts demand swings and adjusts orders in real time.

- Self-optimizing inventory: Inventory levels adapt dynamically based on consumption patterns and risk signals.

- Autonomous warehouses: Robotic picking, automated sortation, and real-time rescheduling reduce human bottlenecks.

These capabilities begin within supply chain management systems that can ingest data from every link in the chain sales, logistics, finance, and operations and then apply algorithms that take action instead of just reporting.

Why It’s Important

According to industry data, automation can increase fulfillment efficiency by up to 25% and reduce labor costs by 15–20% when properly implemented. Autonomous systems also lower error rates and free human teams to focus on strategy rather than transaction processing.

How Companies Are Using It

- AI-based order routing: Automatically assigns orders to warehouses based on capacity, cost, and delivery speed.

- Machine-learning contract compliance: Automatically enforces supplier agreements within the supply chain management software, ensuring terms are met.

- Auto-scheduled logistics: Transportation routes and modes are selected without manual intervention.

The shift to autonomous operations isn’t optional, it’s a survival tactic for companies facing margin pressures and demand volatility.

Trend 3: Resilience Through Sustainability and Circular Supply Chains

Sustainability as a Strategic Driver

In 2026, sustainability and resilience are inseparable. Rather than treating environmental goals as add-ons, top performers embed sustainability into the core of their supply chain management system. This means designing networks that aren’t just efficient, but also regenerative and adaptable.

What This Trend Entails

Companies are using modern supply chain management platforms to support:

- Circular supply chains: Products are designed for reuse, remanufacturing, and recycling.

- Carbon-aware planning: Logistics and sourcing decisions account for emissions, not just cost.

- Supplier sustainability scoring: Performance is tracked for environmental, social, and governance (ESG) metrics.

Sustainability is no longer a checkbox. It’s integrated into operational decisions via real-time data and analytics.

Tangible Business Benefits

Investments in sustainable practices aren’t just ethical, they’re profitable:

- Firms with strong sustainability programs often enjoy 10–20% higher customer loyalty.

- Circular models can reduce material waste by 30–50% and lower cost over time.

- Regulatory compliance becomes proactive rather than reactive.

All of this requires visibility and not just the basic “where is my shipment?” type. It demands supply chain visibility software that tracks emissions, waste, and end-of-life returns across all partners.

Real-World Examples

- Reverse logistics enabled by technology: Products come back through the network and are tracked for refurbishment or recycling.

- Green routing engines: Transportation modules in the supply chain management software optimize for lowest carbon footprint as well as delivery time.

- Supplier scorecards: Sustainability KPIs are embedded directly into procurement workflows.

Embedding sustainability into operational systems transforms risk into opportunity. It builds resilience against resource scarcity, regulatory shifts, and customer backlash.

Why 2026 Is a Pivotal Year for Supply Chain Evolution

Across all industries from manufacturing to e-commerce, supply chains are under pressure. Customers want faster delivery. Competitors want leaner operations. Investors want higher margins.

To meet these demands, organizations must think bigger than point solutions. They must adopt tools that support end-to-end supply chain management and build interconnected, data-driven networks.

Consider these industry realities:

- Digital transformation initiatives now account for more than 50% of supply chain budgets.

- Over 70% of organizations plan to increase investment in supply chain management software this year.

- Visibility and predictive intelligence are ranked among the top three technology priorities for logistics executives.

If you’re not already upgrading to a modern supply chain management system, you’re likely falling behind.

Final Thoughts

The future of supply chain management is clear: integrated, intelligent, visible, and resilient. In 2026, organizations that embrace connected ecosystems, AI-driven insights, and real-time visibility will dominate.

If you want a supply chain that’s lean, adaptive, and profitable, the time to act is now. Invest in the right supply chain management system, leverage advanced platforms, and never stop pushing for deeper visibility and automation. And the answer to that right system is LogiNext. Click on the red button to book a demo today. After all, today’s supply chain strategy is tomorrow’s competitive advantage.

4

@LogiNext