Stop Drowning in Rate Sheets: Centralize Your Shipper Rates in One Click

Take a deep breath if you’re still syncing shipper rates via spreadsheets, email, PDF attachments, or all of it together in one shared drive folder that nobody actually reads through. It can and will get better and, no, you don’t have to be an Excel “wizard” or, worse, hire someone called rate-updater-guy. That’s where freight rate management will come in.

The right software will take what used to took hours to manually compare, frantically re-calculate. All of this from a disorganized mess to something normal and even enjoyable to work through. We’re going to explain the problem, the solution, and how you can help the enterprise not drown in freight rate sheets, once and for all.

What Is a Shipper Rate Chart?

A shipper rate chart is an organized record (typically a spreadsheet or digital format). Which outlines the pricing and terms a shipper has agreed to with a carrier or logistics partner.

Typically includes:

– Delivery cost per zone or lane.

– Weight-based or volume pricing.

– Special handling charges.

– Fuel surcharge adjustments.

– Seasonal pricing tables.

– Fees based on service level agreements (SLAs).

In principle, it should allow for transparent pricing. In practice? Every shipper puts it together differently. Some shipper may submit it as a data table, a dense PDF, or some menu saying, “just look for cell C52, ignore columns F-Z, and charged only on Thursdays.” This is why automated freight rate management can no longer be optional.

The Modern Reality: Too Many Shippers, Too Little Standardization

Currently, enterprise logistics teams are responsible for multiple shippers—each with:

– Different pricing models.

– Unique rate agreements

– Tailored SLAs.

– Personal preferences.

– Neverending clarifications.

You are not just managing shipments. You are managing people, expectations, and a rotating circus of changed spreadsheets.

Studies show logistics teams spend 35–60% of planning time just consolidating rate data as they prepare to make decisions. That’s time lost, which is compounded day after day.

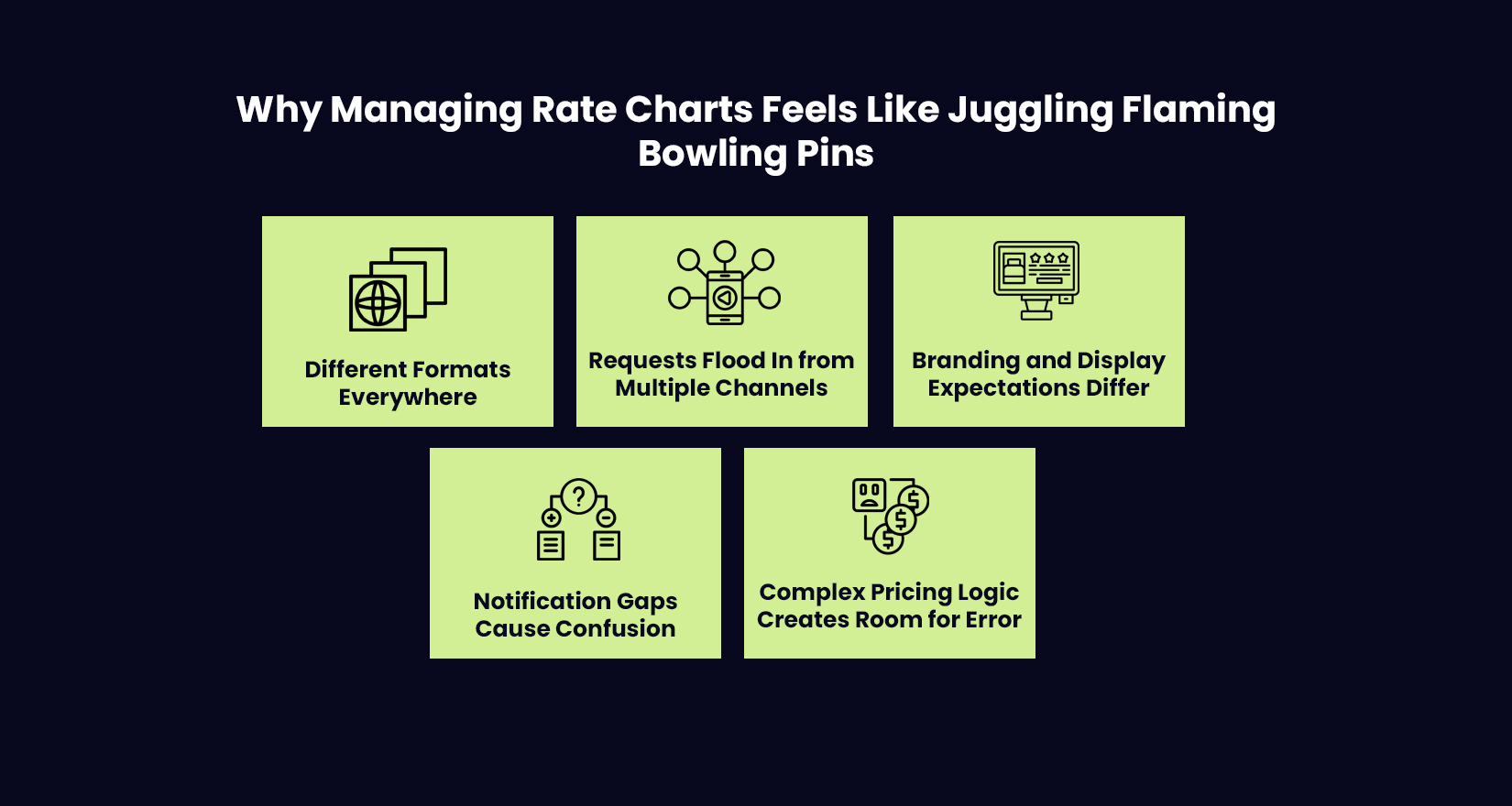

Why Managing Rate Charts Feels Like Juggling Flaming Bowling Pins

1. Different Formats Everywhere:

Every shipper sends rate charts in their own format – Excel sheets, PDFs, Google Sheets, email attachments or just the vague response of “check the last thread.” This drives your team to constantly interpret and re-interpret work, instead of simply applying it.

2. Requests Flood in From Multiple Channels:

Shipment requests don’t come in just one clean workflow. They come through various streams, including emails, phone calls, WhatsApp groups, forwarded screenshots, and shared folders. The most cumbersome task becomes not processing shipments, but locating the details in the first place.

3. Branding and Display Expectations Differ:

Every shipper would like the platform to look and feel like “their system.” This can lead to endless formatting, naming conventions, and labeling customizations. Ultimately you find yourself operating the same process at least a dozen different ways for the sake of each shipper.

4. Notification Gaps Cause Confusion:

Someone, somewhere is always “not notified” because notifications aren’t standardized. This creates small misunderstandings that escalate into something large. Your team is firefighting, rather than managing.

5. Complex Pricing Logic Creates Room for Error:

Rate charts are not just numbers. They capture lane-based pricing, weight brackets, fuel surcharges, exceptions, and temporary changes. If every shipper defines pricing differently, the manual aspect of calculating them means error is always lurking.

In summary: the number of variables causes instability in determining rates. The manual process becomes a continuing game of catch-up—one mistake from cost leakage and operational confusion.

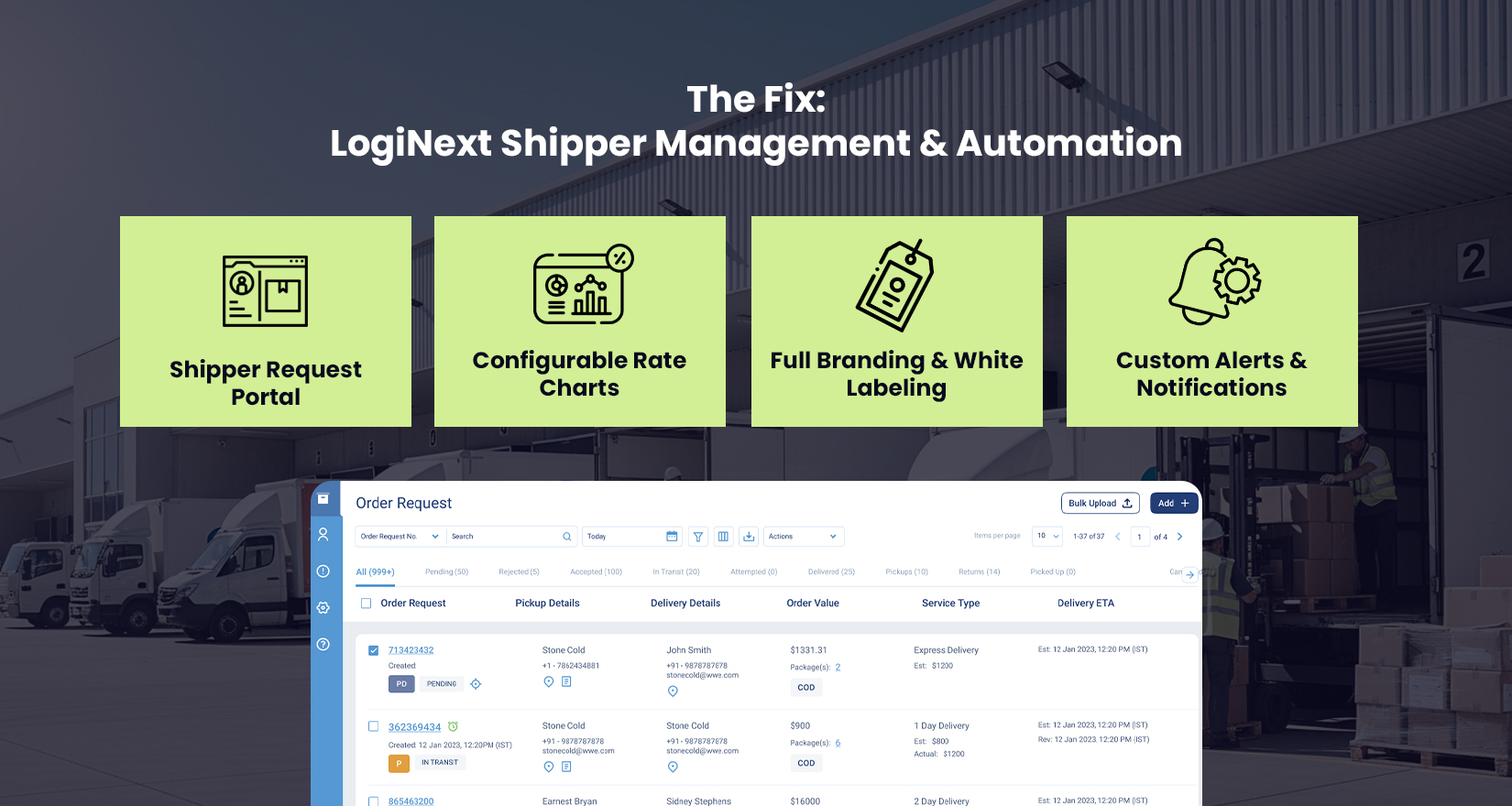

The Fix: LogiNext Shipper Management & Automation

You won’t have to reboot your logistics stack to bring your shipper operations together—it will simply involve rounding up the chaos into one centralized system. This is something we, at LogiNext, do every day. We centralize every shipper, every rate card, every request, and every workflow into one unified interface.

1. Shipper Request Portal:

Instead of spending your time running around trying to figure out the shipment request from random phone calls, chats, and emails, shippers can simply raise requests through a portal. It’s all the same process, clear and traceable. No more figuring out what they said and when.

2. Configurable Rate Charts:

Carriers can upload their unique pricing structure once, and the system automatically applies the structure for every request. No additional lookup, re calculation of categories. No “wait, which version is this?” Just a simple, accurate price every time.

3. Full Branding & White Labeling:

The platform is built for your business to take center stage. The shipper views a clean, professional interface that shows your brand—not a third-party solution. This reinforces trust which keep your logistics identity alive.

4. Customer Alerts & Notifications:

Everyone is notified at the appropriate place in the process—shipment confirmations, dispatch updates, delivery events, exceptions and more. Standardized communication means there are no missed updates, and no escalation that could have been avoided.

It’s not just organization – it’s automation built intentionally, with controls, visibility, and workflow discipline baked in. The result? A logistics operation that feels less like chaos management and more like execution excellence.

What This Solves (AKA: The Sanity Restoration Phase)

1. Zero Manual Data Stitching:

No more moving data from five different sheets, old emails, or historical folders. Data flows straight from shipper inputs into the system and is clean and consistent.

2. Zero Pricing Confusion:

Rates automatically pull in based on pre-configured logic so there is no guesswork or interpretation error.

3. No More “Check the Latest Version” Debates:

There is one living link that’s the authority on rates, it will always be up-to-date and valid.

4. One Unified Workflow Across all Shippers:

Everyone is working from the same repeatable system.

The Efficiency Gains Are Not Subtle

Organizations that rely on freight rate management software unanimously identify bona fide operational improvement. Pricing decisions speed up 20-40% because time previously spent searching, comparing, and validating rate inputs for pricing decisions are eliminated. Organizations see an increase of up to 90% decrease in freight rate errors because calculations are automated instead of manually interpreted, and most teams regain 15-25 hours per week previously consumed on manual freight rate lookup and verification.

In addition to this, when freight rate calculator software is installed on freight rate management systems, pricing is accurate, consistent, traceable and audit-ready and ready for audit. This isn’t just workflow improvement – it is a workflow upgrade.

Also Read: Optimizing Shipping Costs with Rate Charts in Logistics Management Software

Conclusion

If your logistics operation is scaling – or would like to – manual rate management will slow down everything. Spreadsheets and email updates simply will not keep up with shipment volume, types of shippers and pricing complexity. The decision to consolidate all pricing and purchasing under an automated freight rate management system isn’t just an upgrade – it is how fast moving logistics teams stay in control, transparent, and stable in operations.

It gives time back to your teams and clarity to your customers. It makes logistics run instead of react. Want to see a demo? Book a demo with LogiNext and experience a better, smarter, centralized rate workflow.

54

@LogiNext