LogiNext WMS: Transforming Warehouses Into High-Performance Hubs

In today’s briskly moving supply chain environment, warehouses transcend mere storage facilities. They represent essential hubs dictating the effectiveness and triumph of full logistics processes. Given that e-commerce, omnichannel retail, and burgeoning customer demands are stretching capacity, enterprises are facing significant imperatives to operate more intelligently and rapidly. This situation highlights the importance of warehouse management software (WMS). And LogiNext’s WMS is establishing a fresh standard for excellence in warehouse optimization.

Why Traditional Warehousing Falls Short

Conventional depot activities frequently depend upon manual methods, disjointed structures, and responsive direction. Based on a 2024 analysis issued by Grand View Research, enterprises forfeit as much as $1.3 million each year because of subpar stock control and ineffective workflows. Postponements in selecting, preparing, and despatching orders not solely affect operating expenditures but also client happiness.

The core difficulty is not merely pace—it encompasses exactitude, transparency, and flexibility. Devoid of live data intelligence, storage facilities wrestle with depleted stock, excessive inventory, and unmet arrival schedules. Companies necessitate something beyond simple ledgers and isolated applications; they require an all-inclusive system for warehouse oversight that unites information, workforce, and procedures.

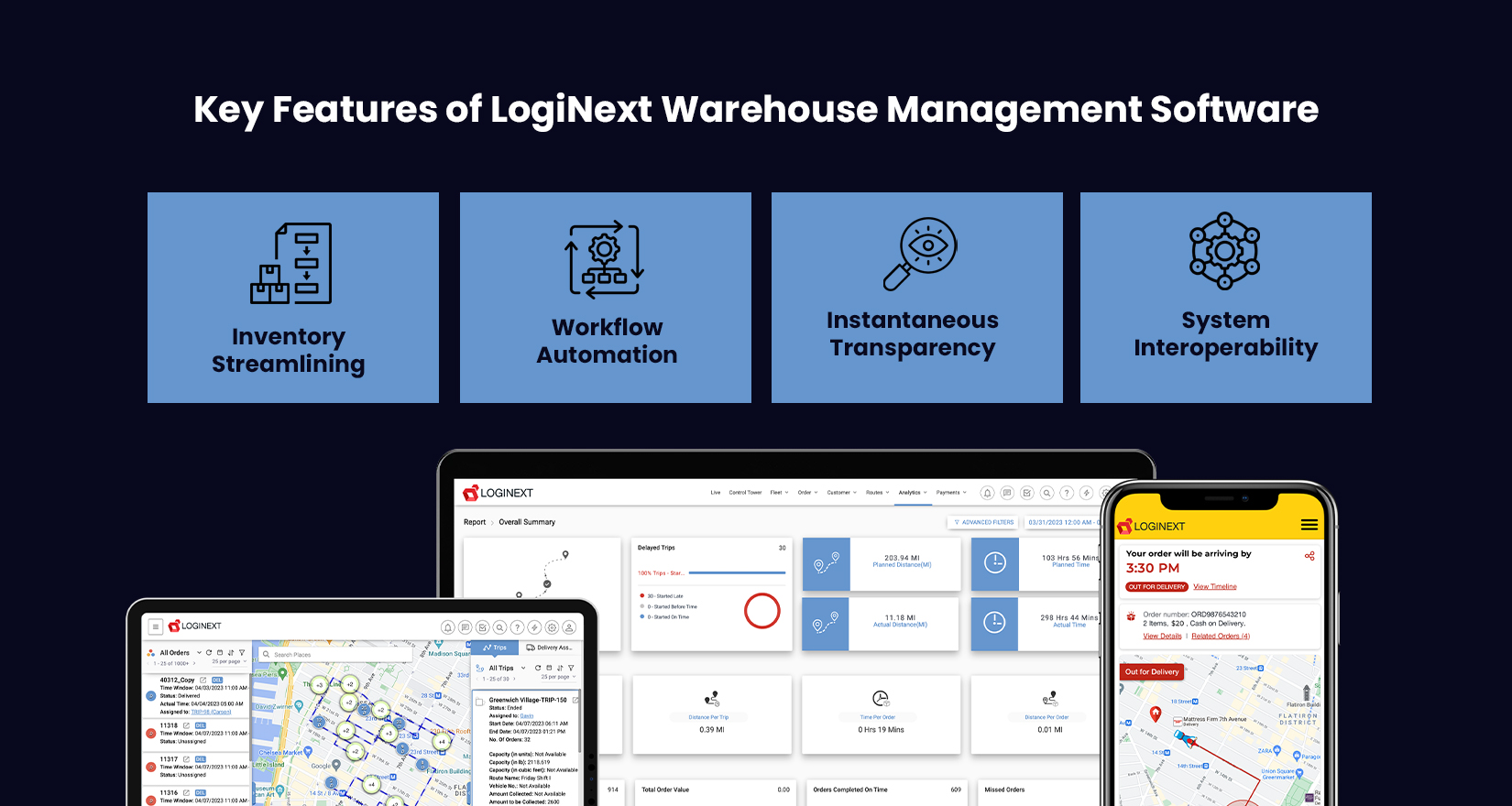

Key Features of LogiNext Warehouse Management Software

LogiNext WMS stands as a contemporary, cloud-based warehouse management system engineered to fundamentally change warehouses into dynamic, high-performance centers. Developed with scalability and adaptability in mind, it delivers a comprehensive perspective on stock, personnel, and operational processes. Through live monitoring, forecasting analytics, and AI-enhanced optimization, LogiNext’s WMS guarantees that every storage facility achieves maximum operational performance.

Among the prominent capabilities are:

1. Inventory Optimization:

LogiNext WMS automates the process of inventory surveillance, substantially decreasing stock variances and mitigating the chances of excessive inventory or product shortages. This capability supports more intelligent, data-led restocking methodologies, guaranteeing that the suitable goods are always accessible precisely when required.

2. Task Automation:

Operational tasks within the warehouse are automatically assigned to employees, taking into account current workload and essential priorities. This improves the distribution of labor resources, minimizes unproductive periods, and boosts overall output.

3. Real-Time Visibility:

A dynamic dashboard offers comprehensive insight into incoming orders, outgoing shipments, and current stock holdings, allowing for quicker, evidence-based strategic choices.

4. Integration Capabilities:

The platform effortlessly connects with ERP, TMS, and various e-commerce platforms, facilitating a fluid and interconnected ecosystem across the entire supply chain.

By deploying LogiNext’s warehouse management software, organizations can anticipate an up to 25% reduction in running expenses. Based on internal metric evaluations, while simultaneously enhancing the precision of order fulfillment and overall handling capacity.

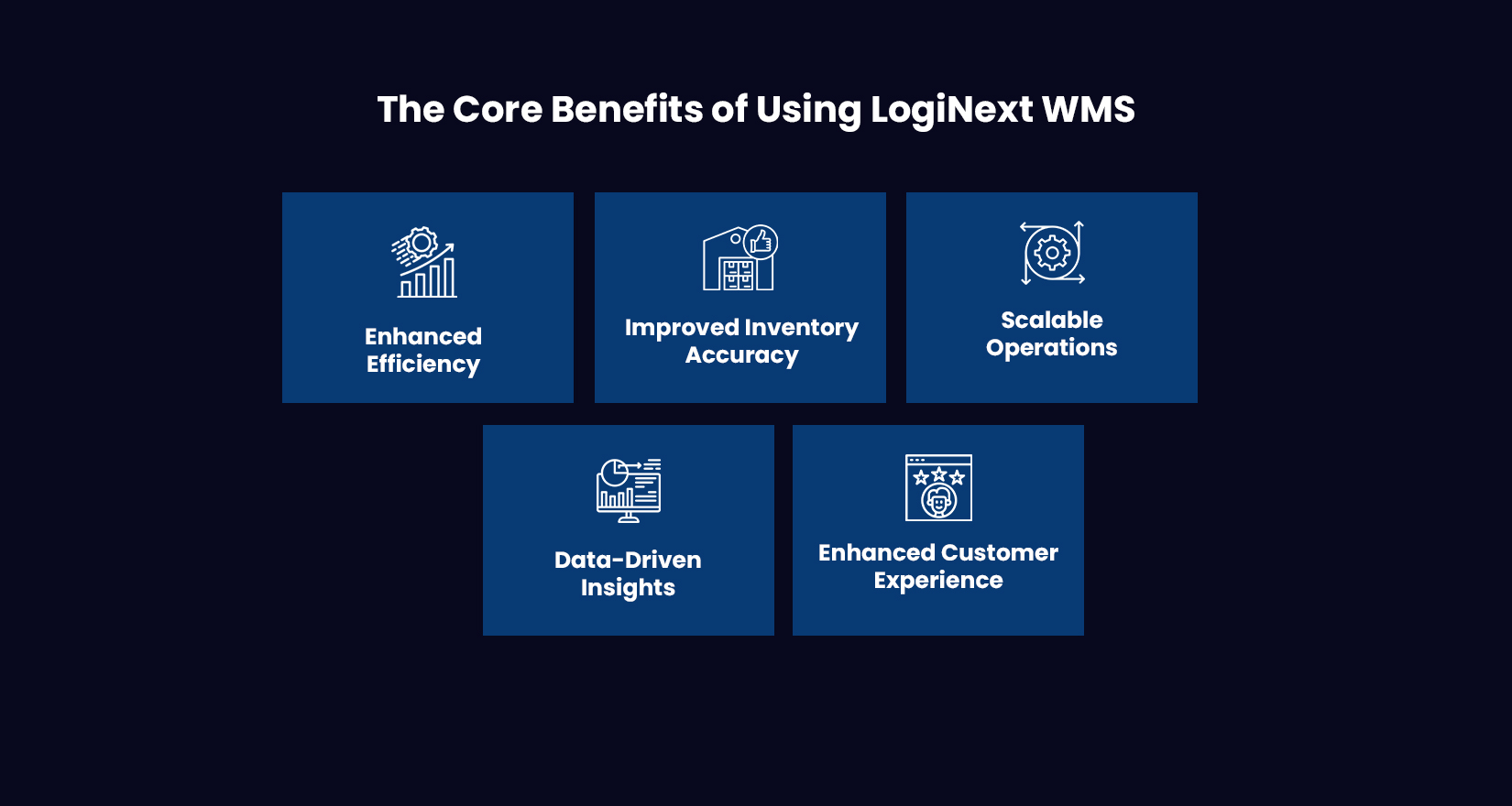

The Core Benefits of Using LogiNext WMS

1. Enhanced Efficiency:

Efficiency is the lifeblood of any warehouse business. Manually tracking inventory methods and old systems only create inefficient workflow and wasted space and resources. The LogiNext WMS leverages automation and AI algorithms to improve the picking, packing, and shipping processes. With reduced manual tracking, warehouses, on average, can increase processing speed by as much as 40% leading to quicker fulfillment of products and better service levels.

2. Improved Inventory Accuracy:

Inventory inaccuracies are a hidden cost for most companies. Lost or misplaced items, overstocked items, and/or stock outs can bring operations to a halt. Less importantly, can be damaging to your customer trust. A robust warehouse management system like LogiNext provides accurate real-time tracking of inventory levels. Smart alerts inform managers of low stock, high demand items, or discrepancies in stock levels. Thereby, reducing human error and delivering 99.5% or better accuracy in inventory tracking.

3. Scalable Operations:

Today’s modern warehouse operations need to scale quickly in responding to fluctuations in demand. LogiNext WMS is designed to be flexible. It accommodates small next-day fulfillment centers and large multi-location warehouses. Features such as dynamic slotting and automated replenishment, include adaptive workflow management that allows a business to scale its operations with more simplicity and less complexity.

4. Data-Driven Insights:

A solid warehouse management system does more than just improve process automation; it gives you data you can act on as well. The analytics module within LogiNext WMS will allow you to track metrics like the order processing time, picking accuracy, and labor productivity. With this information, managers can pinpoint bottlenecks, create a demand forecast, or make evidence-based decisions that benefit operations.

5. Enhanced Customer Experience:

In a world where same or next day shipping is becoming the norm, warehouse productivity plays a key role in customer satisfaction. By improving picking accuracy, reducing times you are not shipping, and providing accurate expected shipping updates, LogiNext WMS gives the end user an unparalleled experience. Research has shown that companies that use warehouse management software are likely to see a 15%–20% increase in customer retention. Thus, validating the nexus between effective warehousing and a customer’s penchant for brand loyalty.

The Technology Behind LogiNext Warehouse Management Software

LogiNext’s WMS incorporates cutting-edge technology for a modern warehouse experience. :

1. Artificial Intelligence & Machine Learning (ML):

Utilizes sophisticated algorithms to anticipate future demand patterns with precision. Thereby, enhancing picking and packing route optimization. Plus, optimize resource utilization as seamlessly as possible, so that the warehouse is functioning at maximum capacity.

2. IoT Integration:

Integrates with smart devices, sensors and equipment to allow for real-time tracking of assets, accurate monitoring of environmental conditions, and improvements in overall operational visibility and control.

3. Cloud-Based Platform:

Provides centralized access from any device, enables managers to oversee, analyze, and manage warehouse operations from anywhere, anytime. Also, provide maximum flexibility without being tied to a physical space.

4. Mobile Applications:

Provides warehouse staff with handheld devices to scan products, quickly assign and allocate inventory, update inventory, and process customer orders quickly and accurately on the floor.

The integration of cutting-edge technology ensures that LogiNext WMS is not simply software. It is a complete warehouse management system that evolves and adapts to your business needs.

Real-World Impact

Numerous businesses have already witnessed the benefits that LogiNext WMS has provided. For example, one regional e-commerce distributor improved their order processing time by 35%, reduced inventory discrepancies by 90%, and sped up delivery cycles. This lead to better customer satisfaction scores.

A second case study from a 3PL provider demonstrated that after implementing a warehouse management solution into their processes. They rid the customer of excess paperwork, improved warehouse layout, improved allocation of workforce. And they were able to scale without additional staffing during peak seasons. The actual results from these options show that a modern WMS is transformational.

Conclusion

Today, warehouses are not just a place for storage, they are dynamic sites to drive efficiency, accuracy and enable the customer satisfaction needed for the modern retail environment. We live in a world of increasing complexity. Outdated systems can be costly mistakes for businesses relying on this technology. LogiNext WMS provides an end-to-end warehouse management system that integrates technology, automation, and analytics to redefine warehouse operations into a high performing business engine.

LogiNext warehouse management software simplifies the processes and delivers value by optimizing operational expenses, inventory accuracy and efficiency, productivity of your workforce, and customer satisfaction. Any business seeking a competitive advantage in logistics must invest in modern, intelligent solutions like LogiNext WMS. The days of slow, inefficient warehouses are a thing of the past—the next generation of high-performance operations has arrived. So, click on the red button below and book a demo with LogiNext today.

55

@LogiNext