The New Era of Supply Chain Management: Control Towers That Deliver

In today’s rapidly changing environment, supply chain management has shifted from merely the transferring of goods between locations to visibility, speed, and accuracy. An issue that occurs in one isolated area of the chain will have consequences in other areas. Resulting in lost profits and poor customer satisfaction. Gartner states that nearly 70% of supply chain executives are investing in advanced visibility platforms. This is to drive resiliency throughout their operations.

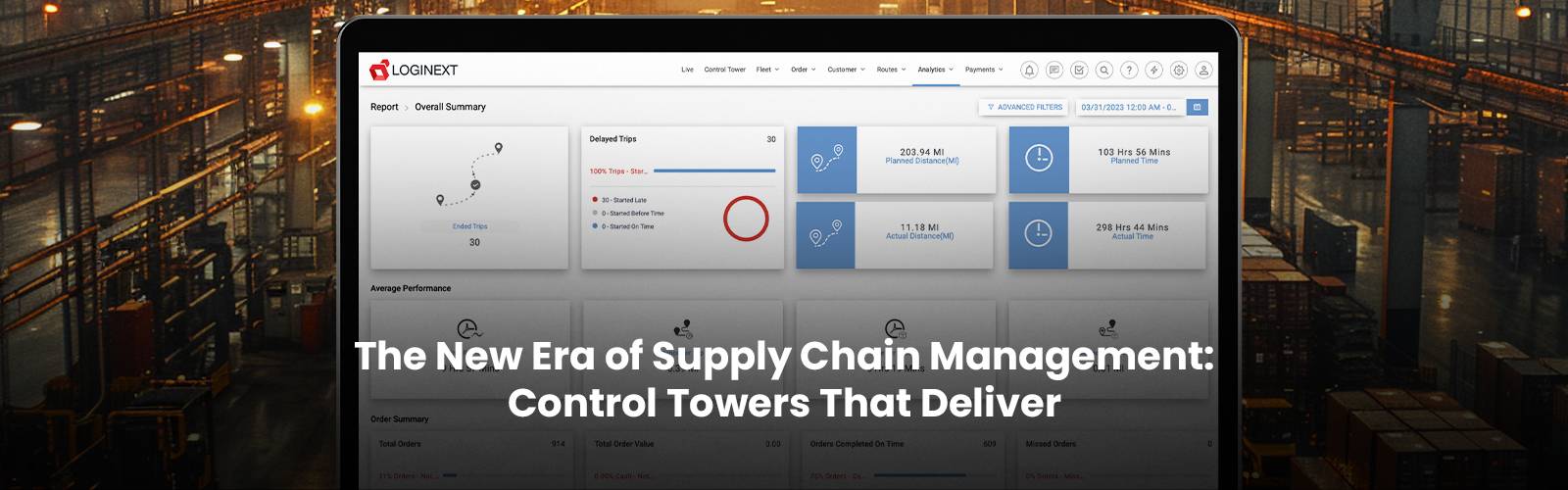

This is where the modern control tower emerges. More than a dashboard, the modern logistics control towers are evolving into intelligent hubs, providing insights in real time, predictive analytics, and flexibility in decision making within one platform. LogiNext’s Control Tower leads this charge by fundamentally changing how companies see their logistics and supply chain operations.

The Evolution of the Control Tower

In the past, logistics was reliant on spreadsheets, siloed systems and phone calls to facilitate activity. This left organizations open to all kinds of errors, delays, and lack of accountability. The concept of a control tower came into play to solve for these deficiencies. Thus, functioning as a centralized nerve center to observe supply chains.

But these earlier iterations of control towers merely displayed data; they did not, specifically, take that data and do anything beneficial with it. These days, expectations are much higher: alerts in real time, routing optimization, predictive analysis, and instant adaptability to disruption. Control towers are not optional; they are the very backbone of supply chain management software and operations.

Why Precision and Flexibility Matter

Logistics is a chaotic world. Fuel prices fluctuate. Weather events complicate transportation. Customers expect faster service. A report from McKinsey says that “abrupt disruptions of supply chains costs companies on average 42% of one year of EBITDA. Both over a decade of the index and representative of companies around the world.”

Precision in logistics is having the knowledge of what the current status of your shipments are at any minute. Flexibility is capable of reacting to that knowledge immediately. The two together create resilience. A modern supply chain management solution driven by a real-time control tower bridges this gap that speaks to providing and processing data into useful information.

LogiNext’s Control Tower: Redefining the Standard

LogiNext has expanded the concept of a control tower beyond the realm of visibility. Control Tower provides:

1. 360-Degree Visibility:

Each shipment, each vehicle, and each driver is being tracked in real-time. This provides managers with the ability to monitor not only where their resources are located, but also to anticipate and forecast possible delays before they occur.

2. Precision Alerts and Notifications:

Instead of inundating teams with waves upon waves of irrelevant data, the service provides the clarity to address only that information that matters. Whether it is a temperature breach in perishables, or a vendor late to a pick-up. It skims the heap to provide relevant information to the teams, it extends their effectiveness substantially.

3. Flexibility Through Automation:

Using dynamic routing and the machine-learning of an artificially intelligent (AI) platform, LogiNext’s Control Tower ensures that planned operations are continually delivered. If a route is obstructed due to an accident, it will automatically find the most optimal alternative route.

4. Integration with Supply Chain Management Software:

Control Tower is not just a stand-alone service. It seamlessly integrates into a broader logistics, supply chain planning, and operations solution. Thus helping to provide workflows from planning to execution to analysis.

This type of precision and flexibility solves the problem of shift management across the full operations function. It does by moving organizations away from reactive firefighting to proactive decision making.

The Business Impact of a Modern Control Tower

The benefits of using a real-time logistics control tower extend across industries:

1. Faster Deliveries:

Firms that take advantage of advanced visibility platforms have been able to substantially increase their operational efficiencies, often realizing an increase in on-time delivery rates of 15–20%. These advanced visibility platforms remove blind spots and make coordination easier, creating faster and more dependable deliveries to customers.

2. Lower Costs:

By rerouting in real-time, the amount of wasted miles decreases, idle time is reduced, and unnecessary labor and fuel costs are trimmed back. DHL states that companies with high visibility in their supply chain realize a 12% annual cost savings with logistics, and that efficiency matters to your bottom line.

3. Improved Customer Experience:

Customers receive instant updates and accurate ETAs, so they’re in the know the whole way. This creates transparency and instills trust which cuts down inquiries and improves loyalty, which makes your company more competitive.

4. Risk Mitigation:

Whether related to regulatory compliance, weather delay, or unforeseen disruption, we take proactive measures to address risk.

We bring accuracy to decision making and flexibility to action, and with LogiNext’s Control Tower offersyour business the ability to scale without uncertainty.

Control Tower in Action: A Real-World Example

Imagine a retailer operating thousands of last-mile deliveries each day. During peak shopping times, customer demand spikes, routes become congested, and mistakes are amplified.

Using a traditional system, dispatch managers and supervisors rush to manage drivers and make manual schedule changes, creating delays and dissatisfied customers.

Now think about the same scenario but with LogiNext’s Control Tower:

– Managers see expected bottlenecks in real time.

– The system automatically suggests alternate routes to avoid traffic congestion.

– Customers receive proactive communication about their orders.

– Managers receive precision alerts when unforeseen delays occur so they can take proper corrective actions in time.

In the end, this means more efficient operations, cost savings, and an improved customer experience in real time with a supply chain management solution built for that purpose.

Looking Ahead: The Future of Logistics Control Towers

The following evolution of control towers will rely on AI, machine learning, and predictive analytics. Not only will these new tools respond better to disruptions happening in the moment. They will also be able to anticipate disruptions in advance. For example, three days ahead of a storm, the platform will be able to inform you that shipments will be affected. Similarly, social media trends will inform demand surges a few weeks ahead of time.

As the supply chain management software organizations have adopted today begin to include predictive intelligence in their design, organizations will not be monitoring supply chain movements, but will be anticipating them. Flexibility will evolve into agility, and precision in supply chain activities will improve with every dataset refreshed.

LogiNext is already paving a path here. Their Control Tower ensures that logistics outcomes are relying on automation-first and AI-driven algorithms. It is not merely keeping pace with logistics trends, it is leading them.

Conclusion

Precision and flexibility are no longer nice-to-have options in logistics, but necessities. A modern control tower combines both precision and flexibility, fundamentally changing what it means to manage a global supply chain. Through integration with advanced supply chain management solutions, businesses can cultivate resilience, reduce costs and increase customer confidence.

LogiNext’s Control Tower is an example of this evolution. With a blend of real-time visibility, predictive intelligence, and integrated connectivity with supply chain management solutions, LogiNext’s Control Tower enables businesses to convert complexity into clarity.

As disruption is the only condition for the future, having a control tower that provides precision and flexibility is not just seen as a competitive advantage, it is survival.

35

@LogiNext