Turning Returns Green with Reverse Logistics Software

In an era where environmental responsibility is no longer optional, businesses are turning to smarter technologies to drive sustainability. One such game-changing innovation is Reverse Logistics Software. More than just a tool for managing returns, this software plays a pivotal role in reducing waste, conserving resources, and building a circular supply chain.

According to the World Economic Forum, reverse logistics operations can account for up to 4% of a company’s total supply chain costs, yet their environmental impact is disproportionately higher. This is where automation and intelligent management can make a meaningful difference.

In this blog, we explore how reverse logistics software empowers business. To reduce waste and embrace sustainability- without compromising efficiency or profitability.

Understanding Reverse Logistics Software

Reverse Logistics Software refers to a digital platform that helps companies manage the return journey of goods. Whether it’s for returns, repairs, refurbishing, recycling, or disposal. Unlike traditional logistics software that focuses on outbound deliveries, this system actively manages the complex, multi-directional flow of products moving backward through the supply chain.

The software integrates with inventory systems, transportation networks, and customer service platforms to streamline every phase of the return cycle.

By using a robust reverse logistics system, businesses can automate return authorization, track assets, and determine the best reuse or resale strategy. It also helps manage end-of-life product disposal while reducing manual intervention and error.

The Sustainability Challenge in Reverse Logistics

Every year, over 5 billion pounds of returned goods end up in landfills, especially in industries like fashion, electronics, and e-commerce. Many of these items could be resold, repaired, or recycled. However, companies often lack the infrastructure to make that happen efficiently.

Sustainability goals are now front and center in corporate strategies, but meeting them requires real-time visibility, automation, and data-driven decision-making. This is exactly what reverse logistics technology offers.

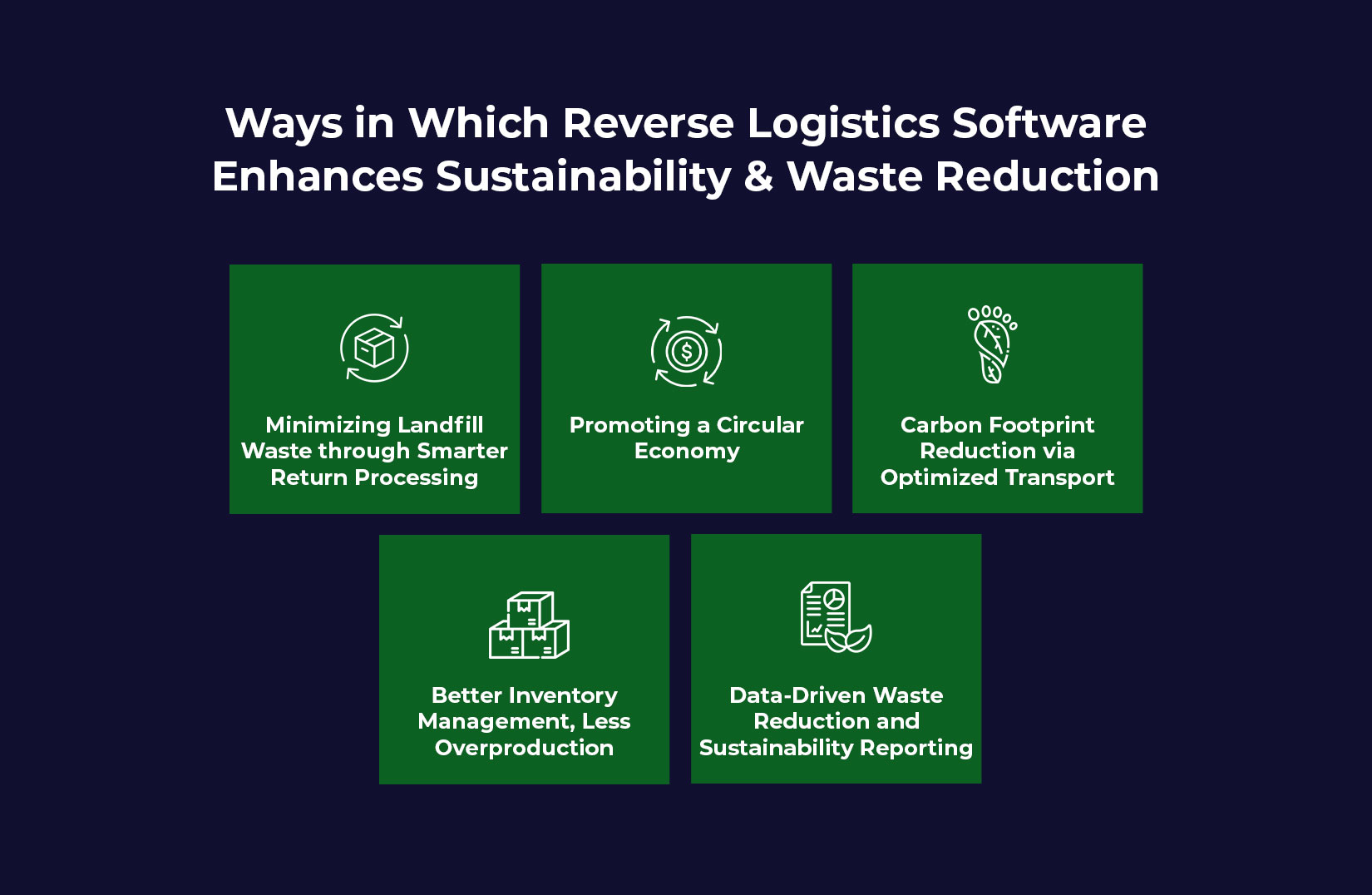

Ways in Which Reverse Logistics Software Enhances Sustainability & Waste Reduction

1. Minimizing Landfill Waste through Smarter Return Processing:

One of the most direct impacts of reverse logistics software is the reduction in landfill contributions. The software intelligently routes returned items to the most sustainable destination- whether that’s restocking, resale, refurbishing, or recycling.

For example, if a returned laptop is still in working condition, the system might flag it for refurbishing and resale instead of disposal. This approach reduces electronic waste and preserves raw materials that manufacturers would otherwise need to produce a new product.

Through automated decision trees and AI-based evaluations, companies can cut down on waste and even monetize returns more effectively.

2. Promoting a Circular Economy:

A reverse logistics solution enables companies to adopt circular economy principles, where products are reused, recycled, and kept in circulation for as long as possible.

Here’s how it works:

– Items returned by customers are assessed quickly using automated software workflows.

– Products in good condition are restocked or redirected to secondary markets.

– Damaged goods are either repaired or disassembled for parts.

– Non-recoverable items are disposed of responsibly, with detailed documentation for compliance.

This cycle reduces environmental impact. However, it also extends product life cycles and reduces the need for new raw materials.

3. Carbon Footprint Reduction via Optimized Transport:

Transportation is a major contributor to greenhouse gas emissions in logistics. Reverse logistics software helps reduce emissions by optimizing the transportation of returned goods.

Smart routing, load consolidation, and real-time tracking reduce the number of unnecessary trips. Some platforms even allow companies to offer return pickups during scheduled delivery windows, saving fuel and cutting emissions.

A study by Capgemini found that using technology to optimize transport routes can lead to a 17% reduction in CO2 emission. This a critical step toward achieving sustainability targets.

4. Better Inventory Management, Less Overproduction:

Manual or inefficient return handling slows down restocking and reduces visibility into available inventory. This often results in overproduction—one of the biggest sources of waste in manufacturing.

A smart reverse logistics system quickly reintegrates returned products into inventory. This real-time visibility prevents overstocking, reduces warehouse waste, and minimizes the need for producing new items to replace returned ones.

In industries with high return rates like apparel and electronics, this capability is a game changer.

5. Data-Driven Waste Reduction and Sustainability Reporting:

Regulatory compliance and ESG (Environmental, Social, and Governance) reporting are becoming increasingly important. Businesses need to show measurable impact when it comes to waste reduction and sustainability.

Reverse logistics technology generates detailed analytics on:

– Return reasons.

– Product lifecycle metrics.

– Recovery outcomes (resale, recycle, repair or disposal)

– Environmental impact (CO2 saved, waste diverted)

With this data, companies can identify inefficiencies, reduce unnecessary returns, and improve product quality- all of which contribute to long-term sustainability.

Real-World Example: Electronics Brand Cuts E-Waste by 30%

A global electronics company implemented a reverse logistics solution to streamline their returns and refurbishing operations. Within one year:

– Return processing time dropped by 45%.

– 30% returned items were refurbished and resold instead of discarded.

– The company saved over $1.2 Million in disposal and manufacturing costs.

Integrating automation, predictive analytics, and centralized return handling- all hallmarks of modern reverse logistics software- made these results possible.

Conclusion

Sustainability is no longer a buzzword—it’s a business imperative. Organizations that invest in reverse logistics software not only reduce their environmental footprint but also unlock new efficiencies and revenue streams.By leveraging a robust reverse logistics system, companies can automate complex return processes, reduce waste, and promote reuse. With the right reverse logistics solution, businesses can confidently pursue sustainability goals, improve compliance, and enhance customer satisfaction—all while saving money.

As global regulations tighten and consumer expectations shift, now is the time to embrace reverse logistics technology that supports both the planet and the bottom line. Thus, click on the red button below and book a demo with LogiNext Solutions- to get the best reverse logistics tech saving the planet and your business.

80

@LogiNext